Introduction

We all see stainless steel everywhere in our daily lives. The railing of the staircase at home, shopping mall, and office, the fork and spoon you use, your lunch box, the kitchen sink, the exhaust of your motorcycle, and many components of the car, are all made from stainless steel either fully or partly and this list can go endless.

As the name ‘stainless’ implies, stainless steel items including cooking utensils and domestic appliances do not stain or rust under normal conditions, provided it is maintained properly.

Stainless steel is a superb metal for storing and cooking utensils; it is durable, tough, has a good aesthetic look, and is non-toxic. Stainless steel utensils preserve the taste, quality, and aroma of the food cooked and stored in it.

This article discusses the following subtopics; what is stainless steel, types of stainless steel, applications of stainless steel, why stainless steel is the preferred metal for kitchenware, cookware, and utensils, pros, and cons of stainless steel utensils v/s aluminum utensils, which is good for you and a few frequently asked questions.

What is stainless-steel

You can define stainless steel as a corrosion-resistant alloy of iron, with a minimum of 10.5% chromium. Other elements are Carbon, Manganese, phosphorus, Sulphur, Silicon, Nickel, Molybdenum, nitrogen, etc. Stainless steel is also known as corrosion-resistant steel or CRES.

Stainless steel metal is available in the market as plates, hot and cold-drawn sheets, pipes, rods, etc. Manufacturers use these products to manufacture kitchenware, cookware, utensils, and other domestic and industrial items.

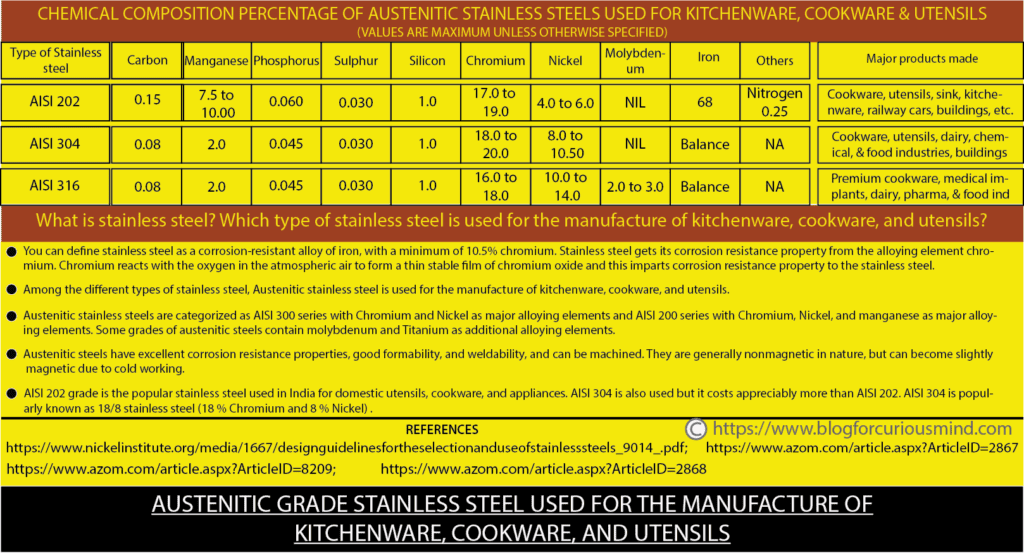

Please study the image below for a detailed chemical composition of the austenitic grade stainless steels that are normally used in the manufacturing of above said items, and kitchen appliances.

Stainless steel gets its corrosion resistance property from the alloying element chromium. Chromium reacts with the oxygen in the atmospheric air to form a thin stable film of chromium oxide and this imparts corrosion resistance property to the stainless steel. This film of chromium oxide can protect the stainless steel from corrosion in the normal atmosphere and exposure to water.

A combination of chromium and molybdenum enhances the resistance to corrosion in the presence of chloride and marine environment. The presence of nickel improves the protection of corrosion resistance in some acidic environments. Nickel enhances the ductility and strength/toughness of stainless steel.

The advantages of stainless steel cookware, kitchenware, and utensils are they are durable, nontoxic, hygienic, and easy to clean; and the disadvantages are they are expensive and take more time and heat to cook.

Types of stainless steel

Stainless steels can be classified in the following ways:

- According to their metallurgical structure

- AISI numbering system as specified by AISI (American Iron and Steel Institute)

- The unified numbering system developed by ASTM (American Society for Testing and Materials) and SAE (Society of Automotive Engineers).

The AISI numbering system (AISI 200, 300, and 400 series) is the popular numbering system used in India, the USA, and many countries in the world, and we shall use this for today’s article.

In the light of the above, stainless steel is broadly classified as under:

- Austenitic stainless steels (AISI 300 and 200 series)

- Ferritic stainless steels (AISI 400 series)

- Martensitic stainless steels (AISI 400 series)

- Precipitation-hardening stainless steel

- Duplex stainless steels

Today’s article is about kitchenware, cookware, and utensils used in the kitchen and these are made from austenitic stainless steel. Hence, we will limit our detailed discussion to austenitic stainless steel only. You can learn more about other categories of stainless steels by going through ‘Design Guidelines for the Selection and Use of Stainless Steels,’ a designer handbook series No 9014 distributed by the Nickel Development Institute (NiDI), or download it by clicking here.

Austenitic stainless steels: Austenitic stainless steels are categorized as AISI 300 series with Chromium and Nickel as major alloying elements and AISI 200 series with Chromium, Nickel, and manganese as major alloying elements. Some grades of austenitic steels contain molybdenum and Titanium as additional alloying elements.

Austenitic steels have excellent corrosion resistance properties, good formability, and weldability, and can be machined. They are generally nonmagnetic in nature but can become slightly magnetic due to cold working.

Austenitic steels have many applications in engineering, food, dairy, and chemical industries and more importantly in the manufacturing of utensils, cookware, and appliances used in your kitchen.

AISI 202 grade is the popular stainless steel used in India for domestic utensils, cookware, and appliances. AISI 304 is also used but it costs appreciably more than AISI 202. AISI 304 is popularly known as 18/8 stainless steel (18% Chromium and 8% Nickel).

Application of stainless steel

You are aware of stainless steel kitchenware, cookware, and utensils for cooking and storing food. But stainless steel has many other applications and some of them are listed below:

- Utensils for cooking and storing

- Kitchen appliances and kitchen utilities; examples are stainless steel kitchen sinks, faucets, refrigerators with stainless steel bodies, food processors with all stainless-steel contact parts (parts in contact with the food being processed), stainless steel knives, and many more.

- Hospital equipment like operation table, cot, and other equipment in the patient room

- Surgical implants like stunts, replacement joints, plates used for joining bones, and similar items are made from high-quality stainless steel.

- Stainless steel is widely used in the construction of buildings, bridges, and other structures. The staircase railing in your home can be stainless steel; it not only lasts long but also improves the aesthetics. The iron rods used for a concrete bridge can be replaced by stainless steel rods to enhance the life span of the bridge by two or three times.

- Stainless steel is extensively used for building carriages for passenger trains and metro.

- Equipment, machinery, tanks, and connecting pipes used in the chemical, dairy, and food processing industries are made using high-quality stainless steel.

- Rail and road tankers for the transportation of milk and other food products.

- In the manufacturing of aircraft and spacecraft.

- Marine industry; many parts of ships and submarines are made from high-quality molybdenum stainless steel that can sustain the marine atmosphere.

Why stainless-steel is the preferred metal for kitchenware, cookware, and utensils?

Stainless steel kitchenware, cookware, and utensils have the following advantages:

- Has very good corrosion resistance and when maintained properly, it does not rust or stain when exposed to air and normal water.

- Very hygienic, easy to clean and maintain.

- The food cooked or stored in a stainless-steel utensil will retain its original taste and aroma since stainless steel does not react with the food.

- Stainless steel is non-toxic.

- A well-maintained stainless-steel utensil will retain its shine and aesthetic look for a long time.

- You have a choice of stainless steel kitchenware, cookware, and utensils made from AISI 304 and AISI 202 grade stainless steel. Both are good but well-maintained AISI 304 utensils and kitchenware will last for your lifetime. AISI 304 is for those who want superior quality and AISI 202 is for those with tight budgets.

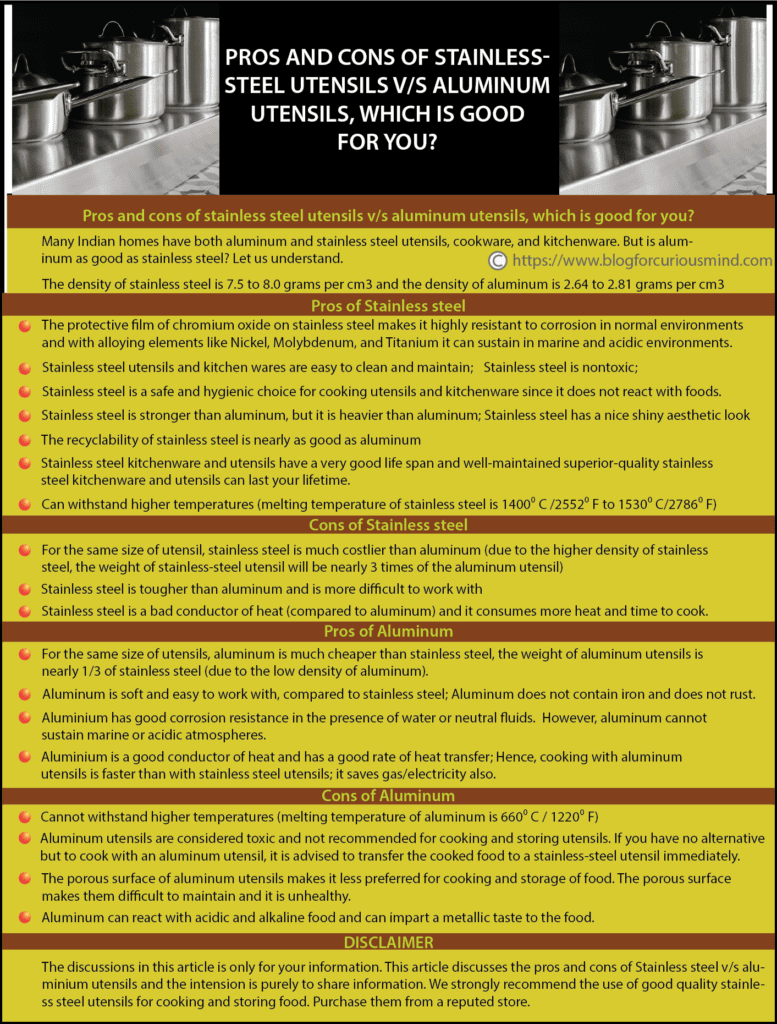

Pros and cons of stainless-steel utensils v/s aluminum utensils, which is good for you?

The density of stainless steel is 7.5 to 8.0 grams per cm3 and the density of aluminum is 2.64 to 2.81 grams per cm3

Stainless steel

Pros

- The protective film of chromium oxide on stainless steel makes it highly resistant to corrosion in normal environments and with alloying elements like Nickel, Molybdenum, and Titanium it can sustain in marine and acidic environments.

- Stainless steel utensils and kitchen wares are hygienic, nontoxic, easy to clean, and simple to maintain.

- Stainless steel is a safe and hygienic choice for cooking utensils and kitchenware since it is not reactive to foods. The non-porous surface of stainless steel does not allow retention of food particles on its surface; old food particles on the surface can decay and spoil the food cooked or stored subsequently.

- Stainless steel is stronger than aluminum, but it is heavier than aluminum

- Stainless steel has a nice shiny aesthetic look

- The recyclability of stainless steel is nearly as good as aluminum (aluminum is known as 100% recyclable). Presently the manufactured stainless steel uses up to 60% recycled stainless steel.

- Stainless steel kitchenware and utensils have a very good life span and can look as good as new for many years. The well-maintained superior-quality stainless steel kitchenware and utensils can last your lifetime.

- Can withstand higher temperatures (melting temperature of stainless steel is 1400⁰ C /2552⁰ F to 1530⁰ C/2786⁰ F)

- Stainless steel is machinable and weldable. Welding stainless steel needs skill (especially TIG welding), but compared to aluminum, stainless steel is much easier to weld.

Cons

- Has a low strength-to-weight ratio compared to aluminum

- For the same size of utensil, stainless steel is much costlier than aluminum (due to the higher density of stainless steel, the weight of stainless-steel utensil will be nearly 3 times of the aluminum utensil)

- Stainless steel is tougher than aluminum and is more difficult to work with (requires higher force to bend and form).

- Stainless steel is a bad conductor of heat (compared to aluminum) and it consumes more heat and time to cook.

Aluminium

Pros

- For the same size of utensils, aluminum is much cheaper than stainless steel, the weight of aluminum utensils is nearly 1/3 of stainless steel (due to the low density of aluminum).

- Aluminum is soft and easy to work with, compared to stainless steel. It is easy to cut, bend, or form aluminum to your required shape.

- Aluminium does not contain iron and hence it cannot rust.

- Aluminium has good corrosion resistance in the presence of water or neutral fluids (aluminum reacts with oxygen in the air and forms a protective film of aluminum oxide). However, aluminum cannot be sustained in marine or acidic atmospheres.

- Aluminium is a good conductor of heat and has a good rate of heat transfer; Hence, cooking with aluminum utensils is faster; it saves gas/electricity also.

Cons

- Cannot withstand higher temperatures (melting temperature of aluminum is 660⁰ C / 1220⁰ F)

- Aluminum utensils are considered toxic and not recommended for cooking and storing utensils. If you have no alternative but to cook with an aluminum utensil, it is advised to transfer the cooked food to a stainless steel utensil immediately.

- Aluminum is difficult to weld and it requires a highly skilled welder to weld aluminum.

- The porous surface of aluminum utensils makes it less preferred for cooking and storage of food. The porous surface may allow the retention of old food particles that can decay and spoil the food cooked or stored subsequently. The porous surface of aluminium utensils makes them difficult to clean and it is unhealthy.

- Aluminum can react with acidic and alkaline food and can impart a metallic taste to the food.

Buying guide for stainless steel utensils, cookware, and kitchenware

A wide variety of stainless-steel utensils, cookware, and kitchenware are available in the market viz. cooking utensils and storing vessels in various shapes and sizes, concave and flat pans (with or without handles), cutleries, bowls, plates, and many more.

Buying guide for stainless steel kitchenware, cookware, and utensils:

- Stainless steel utensils, cookware, and kitchenware are made from AISI 202 and AISI 304 grade stainless steel. The products made from these grades look alike and an ordinary person may not be able to differentiate. Products made from AISI 304 are more durable and if maintained properly, they will lost for your lifetime. Products made from AISI 202 grade are also good but over the years there can be issues like cracking edges, etc.

- Purchase the utensils, cookware, and kitchenware from a reputed store. Some manufacturers of stainless steel metal may compromise the quality by keeping the percentage of Chromium and Nickel less than the standard; obviously, products made from such stainless steel will be cheap but of low quality. In our country, AISI 304 is popularly known as Salem Stainless Steel (AISI 304 stainless steel is produced by the unit of SAIL (Steel Authority of India) at Salem in Tamil Nadu).

- Stainless steel utensils, cookware, and kitchenware are made from sheets and the sheets come in different thicknesses (starting from 0.3 mm up to 6 mm). You should decide the cross-section thickness of the utensil you want to purchase. If you are visiting the shop personally, this is a simple task. You can feel the utensil with your hand and decide which thickness suits your requirements. If you are ordering online, you may have to check the thickness of the existing utensils in your kitchen and decide.

- Handles and lids are an important aspect of a utensil. Ensure the utensils selected have handles that are convenient to you.

- Check compatibility with induction, if you are using an induction cooktop.

- If you have budget limitations, you can consider utensils made from AISI 202 steel.

- Stainless steel utensils clad with aluminum or copper bottoms are also available.

Frequently asked questions on stainless-steel

Why ordinary steel rust and stainless steel (both contain iron) does not rust?

Ordinary steel contains iron and iron corrodes or rusts when it reacts with the oxygen in the air, and the presence of water accelerates the corroding or rusting process. Stainless steel is an alloy of iron, chromium, nickel, and other elements. Chromium in stainless steel reacts with oxygen in the air and forms a protective film of chromium oxide. This chromium oxide film protects stainless steel from corroding or rusting. The percentage of chromium can be from a minimum of 10.5% up to 30%, depending on the grade of stainless steel.

What is the difference between ordinary steel and stainless steel?

The chemical composition of ordinary steel and stainless steel are entirely different and so are their physical properties. The only common thing between them is both are iron-based.

Ordinary steel does not have corrosion resistance, and it rusts quickly in the presence of water. Stainless steel has corrosion resistance and it can sustain in the presence of water.

Is stainless steel resistant to corrosion?

Stainless steel is corrosion-resistant when it is exposed to air in the environment or normal water. However, all categories of stainless steel are not corrosion-resistant when exposed to chemicals.

When AISI 304 grade stainless steel is exposed to 3% sulfuric acid it can retain its corrosion-resistant property at room temperature only. For this reason, AISI 304 is normally not used for storing or handling sulfuric acid and similar substances. AISI 316 grade stainless steel can retain its corrosion-resistant property when exposed to 3% sulfuric acid up to a temperature of 50⁰ C/122⁰ F or 20% sulfuric acid at room temperature.

The freezing point of Brine solution (solution of sodium chloride (NaCl/salt) and water (H2O)) is less than that of ordinary water and hence brine is used as a coolant in heat exchangers for fast cooling of milk or other fluid substances. The material of such heat exchangers is normally AISI 316 grade stainless steel since AISI 304 grade cannot retain its corrosion resistance property when it contacts with a brine solution. For similar reasons, AISI 316 is preferred for ship and submarine parts that are exposed to seawater.

In many cases the corrosion may happen only at some points (localized corrosion); the reasons can be the chemical concentration may be strong at some locations or the temperature of the chemical solution may be higher at some locations.

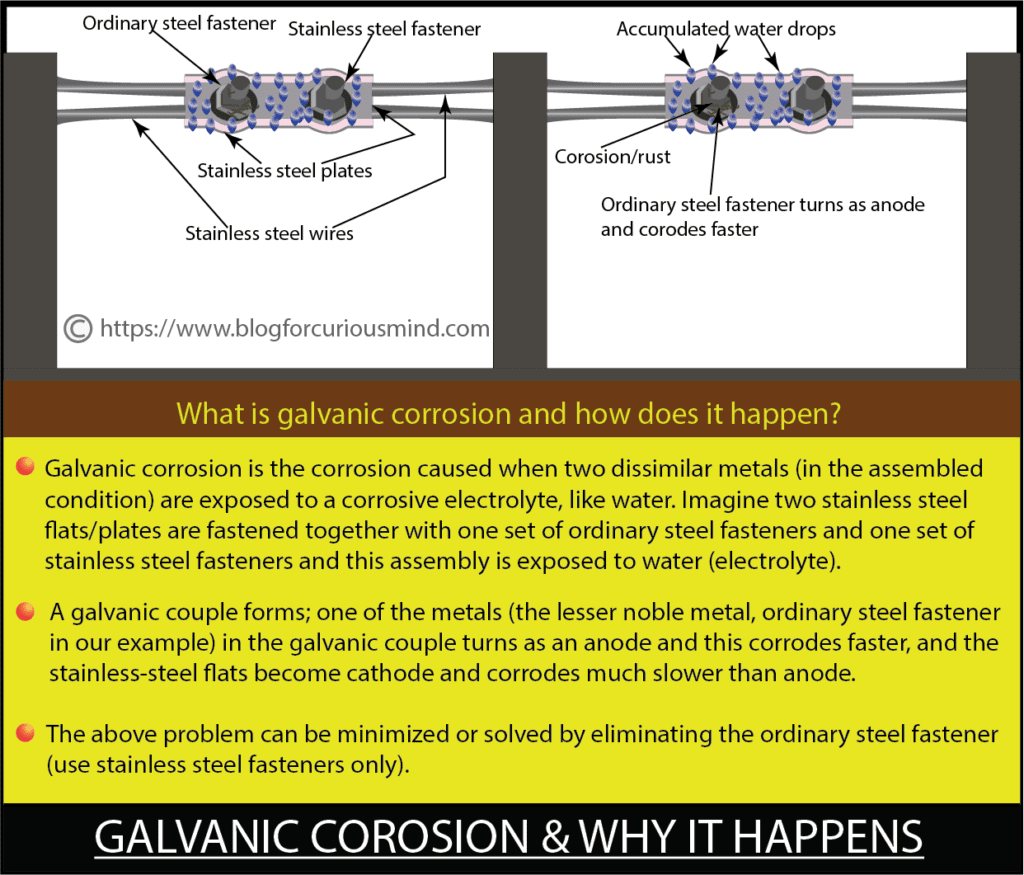

What is galvanic corrosion and how does it happen?

Galvanic corrosion is the corrosion caused when two dissimilar metals (in the assembled condition) are exposed to a corrosive electrolyte, like water. Imagine two stainless flats are fastened together with one set of ordinary steel fasteners and one set of stainless-steel fasteners and this assembly is exposed to water (electrolyte).

A galvanic couple forms; one of the metals (the lesser noble metal, ordinary steel fastener in our example) in the galvanic couple turns as an anode and this corrodes faster, and the stainless-steel flats become cathode and corrodes much slower than anode.

The above problem can be minimized or solved by eliminating the ordinary steel fastener (use stainless steel fasteners only). Watch this YouTube Video.

Are all stainless steel non-magnetic?

No, martensitic, duplex, and ferritic stainless are magnetic (AISI 400 series). Austenitic grade stainless steels (AISI 200 and 300 series) are normally non-magnetic, but austenitic grade stainless steels can become slightly magnetic when they undergo cold forming or when they are cast.

What are the different types of corrosion?

- Corrosion that happens uniformly all over the surface is called general or atmospheric corrosion.

- Corrosion in the form of localized pitting or cavities is called pitting corrosion and this can occur when stainless steel is exposed to chloride atmosphere.

- Localized corrosion at the joints of two different metals or under the gaskets is called crevice corrosion. The reasons can be localized acidic conditions and low oxygen areas.

- Galvanic corrosion.

Conclusion

When you consider kitchenware and utensils for cooking and storing, stainless steel has numerous advantages as brought out in the preceding paragraphs. Stainless steel utensils, cookware, and kitchenware are nontoxic, healthy, durable, and look good in your kitchen. Use a soft scrubber and avoid cleaning agents with harsh chemicals for washing.

Disclaimer: The discussions in this article are only for your information. This article discusses the pros and cons of Stainless-steel v/s aluminum utensils and the intention is purely to share information. We strongly recommend the use of utensils made from AISI 304 or AISI 316 grade stainless steel for cooking and storing food. Purchase the utensils and kitchenware from a reputed store.

References

https://www.azom.com/article.aspx?ArticleID=8209

https://www.azom.com/article.aspx?ArticleID=2867

https://www.azom.com/article.aspx?ArticleID=2868

https://madeincookware.com/blogs/how-to-choose-best-stainless-steel-cookware