Introduction

Pasteurization of milk is a heating process that kills the harmful bacteria in milk. Food and drink products such as wine, and fruit juices can be pasteurized.

The credit for discovering the pasteurization process goes to the French scientist/microbiologist, Louis Pasteur. In the 1860s, he found that the bacteria causing the spoilage of beer and wine could be killed by sufficiently heating them. Also, heating prevents the beer and wine from becoming sour. Later, this method was adopted for milk.

This article takes you through the subtopics, such as what pasteurization of milk is, how the milk is pasteurized, the process of pasteurization in a milk dairy, the advantages of pasteurized milk, and a few frequently asked questions.

What is pasteurized milk?

When raw milk is heated to pasteurization temperature (72° C (162° F) or more) and held at that temperature for a designed time (15 to 20 seconds), the heat kills up to 99.9% of the harmful pathogens (bacteria/parasites) including E.coli and Salmonella.

The raw milk that has undergone a heating process is termed ‘pasteurized milk’. The heating process or cycle is called pasteurization. Further, there can be multiple combinations of pasteurization temperature and holding time. The holding time reduces with the increase in pasteurization temperature. The pasteurized milk is immediately cooled to 4° C (39° F) or less.

Pasteurization makes milk safe for human consumption and increases its shelf life. Raw or non-pasteurized milk contains pathogens (bacteria, parasites, and other harmful microorganisms). Its consumption can cause serious diseases, illnesses, and death.

The milk taken from a healthy cow can have some bacteria and bacteria can also enter the raw milk during milking, handling, transportation, etc. The raw milk may be of any dairy animal viz. cows, buffaloes, goats, etc.

Most countries have laws and regulations stipulating licensed dairy plants to sell milk in pasteurized, cooled, and packaged conditions. Depending on the country’s regulations, milk dairies may add selected vitamins (like vitamins A and D) to the pasteurized milk.

However, pasteurization does not mean you can open the milk container and keep it out of the refrigerator. Even pasteurized milk may have a minuscule amount of retained bacteria which can multiply faster at room temperature. Hence, milk is always stored at 4° C (39° F) or less. Bacterial growth is minimal or negligible at this temperature.

How is milk pasteurized?

The two popular pasteurization processes for milk are:

- High-Temperature Short Time or HTST pasteurization process

- Ultra High Temperature or UHT pasteurization process

Pasteurization by HTST or UHT does not use any harmful chemicals. Also, they do not significantly compromise the nutritional advantages of milk.

The shelf life of pasteurized milk depends on the type of milk (organic or otherwise), pasteurization process (HTST or UHT), type of package (plastic pouch, plastic can, tetra pack, etc.), etc.

HTST pasteurization of raw milk:

In the HTST pasteurization process the raw milk is heated to 72° C (162° F) or more, held at this temperature for 15 to 20 seconds, and then rapidly cooled to 4° C (39° F) or less. The actual combination of pasteurization temperature and holding time can differ from country to country.

The cold milk is packed in plastic pouches, cans, or other packages. Depending on the package type, HTST pasteurized milk can be stored at 4° C (39° F) for 1 or more days. Read the label on the package for the storage instructions and storage period. The HTST pasteurization process is also called flash pasteurization.

UHT/Ultra-High-Temperature pasteurization process or ultra-pasteurized milk:

In the UHT pasteurization process the raw milk is heated to 138° C to 154° C (280° F-309° F) for 2 to 8 seconds and then cooled rapidly to 4° C (39° F) or less. An aseptic method of packaging (packing a sterile product in a sterile packing) is followed for packing UHT pasteurized milk. Also, in the aseptic packaging process, the packaging is sterilized separately.

Ultra-pasteurized milk is packed in sterile and hermetically sealed airtight containers like tetra packs. UHT pasteurized milk in tetra packs can be stored outside the refrigerator for 40 to 60 days. Read the label on the package for the storage instructions and storage period. However, once you open the tetra-packed milk, it should be stored at 4° C (39° F) or less and used within 5 days.

The reason for the long and unrefrigerated shelf life of ultra-pasteurized milk is:

- The UHT process kills almost all the bacteria and

- The six-layer tetra pack protects the milk by blocking the entry of sunlight, germs, and air into the packing.

LTH (low-temperature holding) or LTLT (Low-temperature-long-time) pasteurization

LTH is a less popular method of raw milk pasteurization. It involves heating the milk to a temperature of 63° C (145° F) and holding it for 30 minutes. Then the milk is cooled to 4° C (39° F) or less.

LTLT pasteurization is a low-productive method and has become obsolete. Its use is generally limited to cheese production processes.

Process of pasteurization in a milk dairy

Let us briefly discuss and understand the equipment used for the HTST process of pasteurization of raw milk. HTST is the most popular pasteurization process used for milk pasteurization.

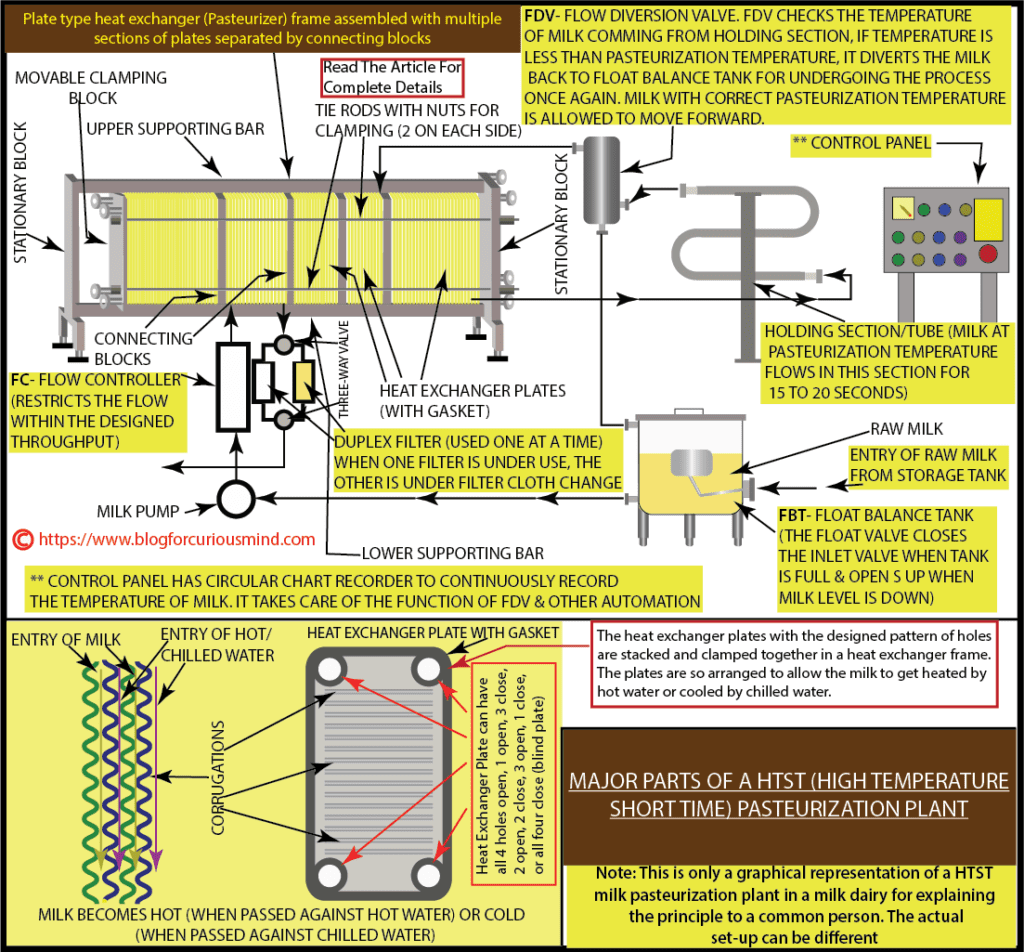

You need a heat exchanger to heat or cool the milk. A heat exchanger is a device that facilitates the heat transfer between two fluids. It can be used for heating or cooling fluids like milk. Plate-type heat exchangers are popular in milk dairies for their efficiency, simple construction, and ease of cleaning.

A plate-type heat exchanger consists of several thin vertical corrugated (grooved) stainless steel plates stacked side-by-side in a frame and clamped together with tie rods. Each plate has a gasket to eliminate leakage between the two plates. The space between the corrugated plates is continuously filled alternately with milk and a cooling or heating medium. So, you have milk on one side, and it can be cooled or heated depending on the medium on the other side (cold water or hot water).

The pattern of flow of fluids is so arranged that if milk is flowing between two sealed plates, hot water is made to flow in between the adjoining plates and milk gets heated due to heat transfer. If cold water is made to flow between the adjoining plates, the milk can be cooled.

A plate-type heat exchanger for pasteurizing raw milk in a milk dairy has different sections. A pack of plates separated by a partition/connection block is called a section. A plate-type heat exchanger with multiple sections can be called a pasteurizer. A pasteurizer facilitates continuous pasteurization of raw milk and the processing capacity can be up to 20000 liters per hour (LPH) or more. The different sections in a milk pasteurizer are:

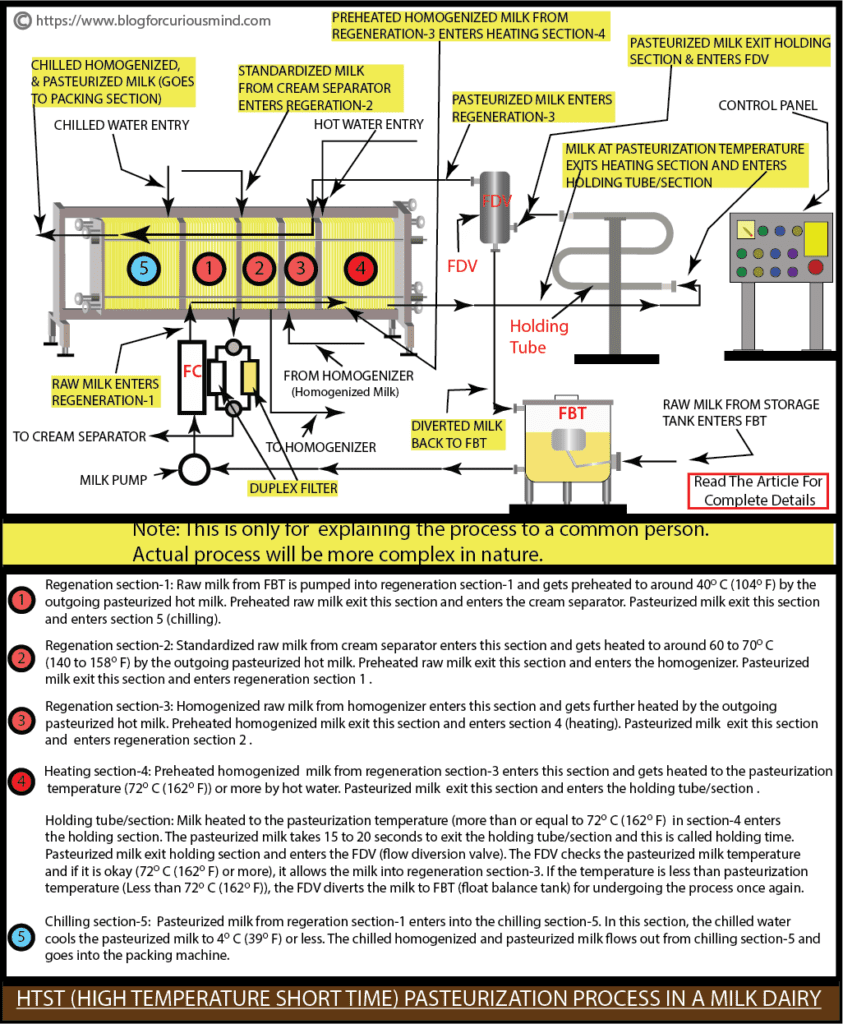

Regeneration sections (1, 2, and 3)

Depending on the pasteurizer design, there can be two or three regeneration sections. In these sections, the outgoing hot pasteurized milk flows against incoming cool raw milk and preheats it. Also, the regeneration section enables heat recovery from outgoing hot pasteurized milk (which otherwise is wasted) and improves the thermal efficiency of the pasteurizer. In the regeneration section, the hot pasteurized milk gets cooled and cold incoming raw milk gets preheated.

This has dual benefits. The cold milk is preheated and the hot milk is cooled resulting in high heat transfer efficiency. The raw milk is preheated to 40° C (104° F) in regeneration section 1 which is suitable for the cream separator. The raw milk is further preheated to 60 to 70° C (140 to 158° F) in regeneration section 2 suitable for homogenization.

The preheated raw milk from regeneration section 3 enters the heating section 4. The pasteurized milk from the holding section passes through the three regeneration sections (3-2-1), gets cooled to around 32° C (90° F), and enters the chilling section 5.

Heating section-4

The preheated raw milk from regeneration section 3 enters heating section 4 and is heated to the pasteurization temperature of 72 ° C (162 ° F) or more. The heating medium used is hot water (hot water is continuously produced by mixing steam and water).

Holding section

The milk from heating section 4 flows into the holding section for the designed pasteurization time (15 to 20 seconds) and then moves into the FDV (flow diversion valve).

The FDV checks the temperature of the pasteurized milk and if it is okay (≥ 72° C (162° F)), the milk is allowed to pass into regeneration section 3. If the temperature is less than 72° C (162° F), the FDV diverts the milk to FBT (float balance tank) to repeat the process.

Chilling section-5

The pasteurized milk from the regeneration section 1 enters the chilling section 5. The milk is cooled to 4° C (39° F) or less using chilled water as the cooling medium.

The chilled milk is taken to the packaging machines for packing in plastic pouches, cans, etc. The packed milk is stored in a cold room at 4° C (39° F) or less till it is transported to the retail stores.

Advantages of pasteurized milk

- Pasteurization kills harmful bacteria (85 to 99.9%) in raw milk and makes it safe for human consumption.

- Pasteurization increases the shelf life and retention of milk quality when stored at 4° C (39° F) or less.

- Studies show that pasteurization does not significantly affect the nutrient value of milk.

- Milk is an excellent source of calcium, vitamin A, etc.

Caution

Always read the label on the milk container before you buy it. Confirm the milk is pasteurized, fresh, and has sufficient use by period (watch for use by date). If you are in doubt, ask the stores in charge and confirm the milk you are buying is pasteurized and fresh.

If you are allergic to dairy products, consult your doctor before consuming milk.

Frequently asked questions

Can I drink fresh milk drawn from a cow?

You will hear people say they drink fresh milk from a cow and are healthy. However, this is not advisable. Many medical reports say consuming raw milk can cause serious diseases, illness, and even death. Hence, it is always recommended to consume fresh pasteurized milk stored at 4° C (39° F) or less.

If you have a milk-able healthy cow in your village/rural home housed in a hygienic shelter, the raw milk from the cow can be consumed after boiling it for 5 minutes. Store the remaining milk at 4° C (39° F) or less. Boil it again before consuming it.

How can I protect my family from diseases/illnesses caused by milk consumption?

Do the following to protect your family from diseases caused by milk consumption.

- Consume pasteurized milk only.

- Purchase pasteurized milk from a reliable and licensed brand.

- Read the label on the package of pasteurized milk to ensure that the milk is fresh, pasteurized, and has sufficient use by date period.

- Store the milk container at 4° C (39° F) or less.

- Boil the stored pasteurized milk before consumption (especially for children and aged people).

- Consume the milk within the specified ‘use by date’.

Note: If you are allergic to dairy products, consult your doctor before consuming milk.

Does pasteurization reduce the nutrient value of milk?

Researches indicate that pasteurized milk retains most of the nutritional benefits of raw milk. Most importantly pasteurized milk is safe for human consumption and has a better storage life.

However, raw milk contains a minuscule amount of Vitamin C that can be lost during pasteurization.

The slight difference in color between raw milk and pasteurized milk is not due to pasteurization. Milk is normally homogenized before pasteurization, and it is the homogenization that makes the milk a bit whiter compared to raw milk.

What is organic milk? Is it necessary to pasteurize it?

Organic milk is produced by feeding the dairy animal with organic food and also the dairy animal is not given harmonic injections to increase its milk-producing capacity.

Raw organic milk is unsafe for human consumption since it can contain harmful bacteria. Hence, it is essential to pasteurize organic milk before human consumption

Is milk an ideal food?

Even though milk is known to be ‘almost an ideal food’, it has deficiencies of iron, copper, vitamin C, etc. Hence, you have to consult your doctor and take the advised supplements.

Conclusion

According to estimates, the daily world milk consumption exceeds two billion liters. Just imagine the havoc it may create if all that milk is consumed without pasteurization. Hence, milk pasteurization and consumption of pasteurized milk are very important for public health. Always read the label on the package of milk you are buying and ensure the milk is fresh, pasteurized, and has sufficient use-by-date. If in doubt, confirm it with the storekeeper.

You may like to read the article ‘What is Homogenized Milk? How milk is Homogenized?’

You may like to read the following articles:

Difference Between Homogenized Milk and Pasteurized Milk

Caution

Always read the label on the milk you are buying. Ensure the milk is fresh, pasteurized, and has sufficient use-by-date.

This article is only for educational purposes. It is not a piece of medical advice. Please consult your doctor for any health queries on milk. Do not add milk to your diet without asking your doctor.

If you are allergic to dairy products, consult your doctor before consuming milk.

References

Outlines of Dairy Technology by Sukumar De (OXFORD UNIVERSITY PRESS)

https://www.cdc.gov/foodsafety/rawmilk/raw-milk-questions-and-answers.html#risks

https://en.wikipedia.org/wiki/Pasteurization

https://www.usdairy.com/news-articles/why-is-milk-pasteurized-4-questions-answered

https://www.organicvalley.coop/blog/difference-between-pasteurized-and-ultra-pasteurized-milk