Introduction

The process of homogenization was invented by the French scientist August Gaulin in 1899. Furthermore, the word homogenization comes from the Greek words ‘homos’ meaning the same, and ‘genos’ meaning kind. Homogenization of raw milk does not involve any harmful chemicals or substances.

This article takes you through the subtopics of elements of cow milk, what is homogenized milk, why is milk homogenized, how milk is homogenized, and the advantages of homogenized milk.

Elements of cow milk

The major components of cow milk are water, fat, protein, lactose, ash (mineral matter), and others including vitamins (B complex, C, etc.), enzymes, etc. Raw cow milk contains 87% water, 3.5 to 4% fat, and 8.5% MSNF (milk-solids-not-fat).

What is homogenized milk?

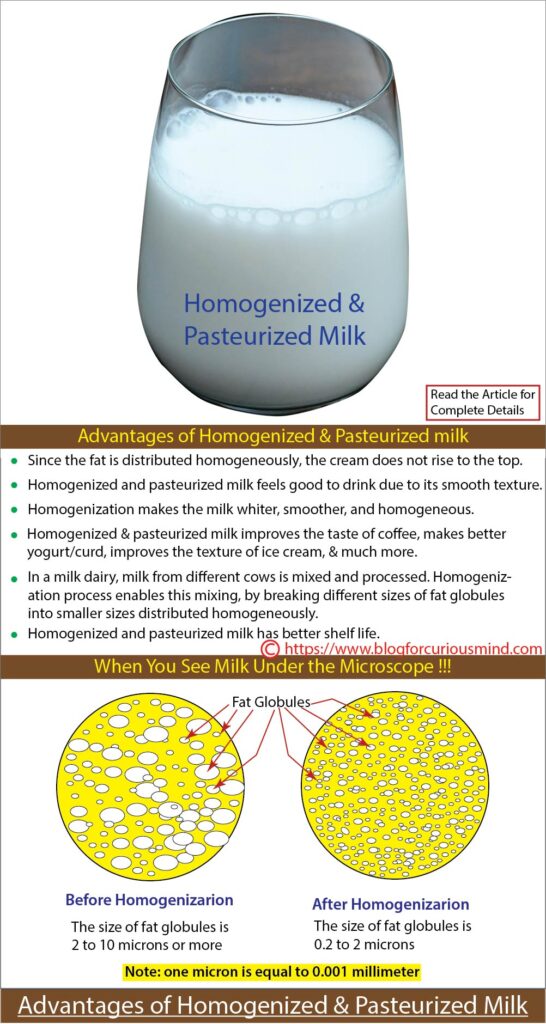

Raw cow milk contains fat globules of sizes varying from 2 to 10 or more microns. One micron is equal to 0.001 millimeters. Additionally, these fat globules can form a cream layer and rise to the surface of the milk.

Homogenization breaks the fat globules of different sizes to bring them down within 0.2 to 2 microns. And these tiny fat globules are distributed evenly throughout the milk. When the milk is properly homogenized, the cream will not rise to the top of the container.

Let us examine an example to understand homogenization. Assume you are preparing a batter for the pancake. When you mix plain flour and skim milk with your hand or a mixer, you will feel the formation of different sizes of lumps of flour. Further, as you break these lumps into smaller particles, and continue mixing, you will achieve a homogenous batter without lumps. You will not feel the lumps since they are broken into minute sizes.

Something similar happens during the homogenization of raw milk. The different sizes of fat globules (2 to 10 microns or more) are broken into an acceptable range of sizes, 0.2 to 2 microns.

However, since you need to homogenize a large quantity of milk, a sophisticated and heavy-duty mechanical machine is required. Milk is pressurized and passed through a homogenization valve to break the varying sizes of fat globules into sizes of less than 2 microns.

So, homogenization of milk can be defined as breaking the different sizes of fat globules in the raw milk into smaller ones by pumping the high-pressure raw milk through a homogenization valve.

The fat content in homogenized and pasteurized cow milk can vary from around 3.5% (whole milk), 1% or 2% (low-fat milk), and 0 to 0.5% (skim milk). However, the fat percentages can vary from country to country.

In most countries, pasteurization of milk is mandatory for milk dairies. However, homogenization of milk is left to the discretion of the milk dairy. So, milk dairies can sell homogenized and pasteurized milk or pasteurized milk.

Why is milk homogenized?

Milk dairies source their milk from numerous cows. Hence, there will be appreciable variation in their fat globule sizes. As a result, all medium and large dairies homogenize the milk to enable the mixing of raw milk from different cows. Therefore, the consumers cannot know that the milk came from different cows.

Homogenization makes the milk a bit whiter, gives a smooth texture, and a homogenous distribution of fat in the milk. Homogenized and pasteurized milk feels good to drink, improves the taste of coffee, makes better yogurt/curd, improves the texture of ice cream, etc.

How milk is homogenized?

Homogenization is a machine-driven process. Different sizes of fat globules (2 to 10 microns or more) in the milk strike a hard surface at high pressure and the result is the fat globules break into small and homogenous sizes. The breaking of fat globules happens inside the homogenization valve.

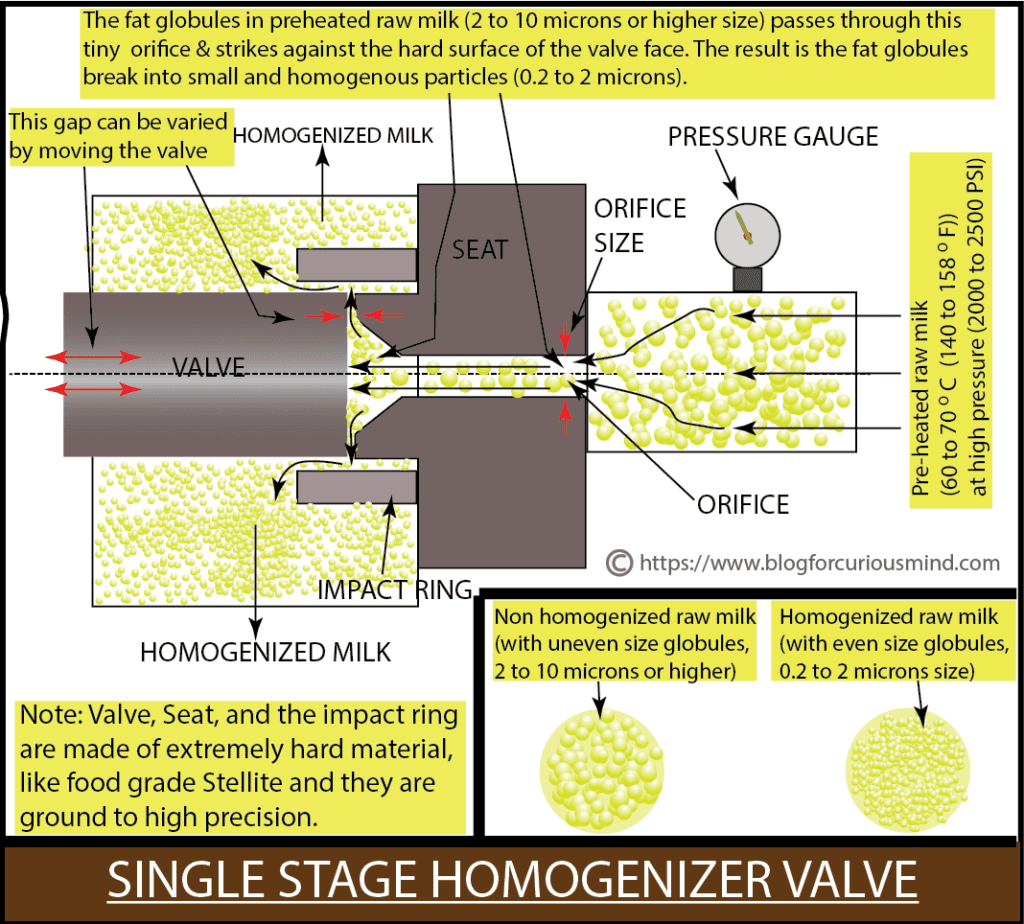

A homogenization valve consists of three components:

- Valve seat with a small orifice in the center

- Impact ring and

- Valve.

These three components are made of hard material like food-grade stellite or equivalent and are ground to high precision. The valve (in the shape of a circular rod) can be moved to reduce the gap between the face of the seat and the valve.

The raw milk to be homogenized should be above the melting temperature of the fat (33° C (91° F) or above) since the fat should be in liquid form for proper homogenization.

The homogenizer has a heavy-duty, 3-plunger, high-pressure reciprocating pump that pumps the preheated raw milk into the homogenization valve. Preheated raw milk (60 to 70° C (140 to 158° F)) at a pressure of 2000 to 2500 PSI (pounds per square inch) is forced into the homogenizer valve.

The high-pressure raw milk enters through the valve seat orifice, strikes against the hard surface of the valve, and exits through the minute gap between the impact ring, valve, and seat. The flow of high-pressure milk through the small gap creates turbulence.

The flow of high-pressure raw milk through the valve seat orifice and the impact of striking on the valve face break the different sizes of fat globules into smaller sizes (0.2 to 2 microns). Hence, the outgoing milk has a homogeneous distribution of fat.

The homogenization process happens fast and continuously. It is done at 5000 LPH (liters per hour) up to 20000 LPH or more.

A single-stage homogenization described above is sufficient for normal cow milk. However, in cases where the raw milk has higher fat content, two-stage homogenization is required.

In such cases, the reduced fat globules may form a cluster after the first stage of homogenization, and such clusters are separated into individual globules during the second stage of homogenization. The second stage of homogenization is done at 500 PSI.

Advantages of homogenized milk

- Since the fat is distributed homogeneously, the cream does not rise to the top of the container.

- Homogenized and pasteurized milk feels good to drink due to its smooth texture.

- Homogenization makes the milk whiter, smoother, and homogeneous.

- In a milk dairy, milk from different cows is mixed and processed. The homogenization process enables this mixing, by breaking different sizes of fat globules into smaller sizes distributed homogeneously.

- Homogenized and pasteurized milk has a better shelf life compared to only pasteurized milk.

However, one drawback of homogenized milk is it is difficult to extract fat from it.

You may like to read the article ‘What is Pasteurization of milk? How the milk is Pasteurized?’

You may like to read the following articles:

Difference Between Homogenized Milk and Pasteurized Milk

Conclusion

The purpose of homogenization of raw milk is to break the large sizes of fat globules into tiny globules that are well distributed throughout the volume of milk. Homogenized and pasteurized milk gives a better feeling when you drink the milk and it tastes good.

So, next time you buy your packaged milk, watch for the words homogenized and pasteurized instead of only pasteurized.

Note: If you are allergic to dairy products, consult your doctor before consuming milk.

Caution

This article is for educational purposes only. This is not a piece of medical advice. Please consult your doctor before consuming milk in any form.

If you are allergic to dairy products, consult your doctor before consuming milk.

References

Outlines of Dairy Technology by Sukumar De (OXFORD UNIVERSITY PRESS)

https://en.wikipedia.org/wiki/Homogenization_%28chemistry%29