Introduction

Like butter, cheese was known to mankind hundreds of years ago, but it was not batch-produced till the 1850s. In those periods, cheese was made in the form using milk of cows, buffaloes, sheep, and goats reared there. The technique of producing cheese in batches started during the period 1860 to 1880.

Due to the policy changes adopted by governments in many countries in the 1900s, animal husbandry and rearing of cows, buffaloes, sheep, and goats for milking and other purposes has come into prominence. This has led to increased milk production. This added with the availability of hygienic stainless-steel temperature-controlled long-distance road tankers resulted in cheese-making dairies receiving surplus milk. At the same time, the demand for cheese was on the rise. Cheese manufacturers started pressurizing manufacturers of cheese-making machines to deliver machines with higher productivity.

The conventional methods of making cheese have become obsolete, and some of the reasons were as follows:

- Making cheese in small and medium-sized batches has become less productive and more labor-intensive.

- Cheese producers were not able to meet the demand for cheese with old and low-productive machines.

- Cheese producers demanded cheese-making machines with higher capacity and productivity, and increased automation to reduce manual labor.

- Cheese producers wanted to utilize the surplus available milk to meet the increased demand for cheese.

The above developments led to the mechanization and automation of cheese-making processes. Dairy technologists and engineers started working on this way back in the 1960s and 1970s. The culmination of the efforts of dairy technologists, engineers, and cheese makers is the availability of continuous cheese-making machines for a variety of cheeses, including mozzarella cheese.

The difference between mozzarella cheese and other processed cheese is mozzarella cheese is made from fresh cheese curd.

Let us discuss and understand how mozzarella cheese is produced continuously.

Mechanization, automation, and continuous production of mozzarella cheese

As the first step towards making cheese-making productive, dairy technologists started mechanizing the cheese-making processes. Most processes, including stirring, cutting of cheese curd, and cooking, were mechanized.

Mechanizing the cheese production processes

As a first step towards achieving continuous cheese production, every cheese-making process should be mechanized and these processes should be responsive to complete automation.

Basic processes of cheese production viz. clarification, standardization, and pasteurization of cheese milk were mechanized and automized during the late 1960s. Pasteurization plants (including centrifuges) with capacities up to 40,000 LPH (Liters Per Hour) or more were available. Over the years these systems have been made more efficient.

Apart from standardization, and pasteurization of cheese milk, all the cheese-producing processes are mechanized. Major mechanized processes are listed below:

- Acidifying (ripening) of cheese milk

- Renneting and coagulation of cheese milk

- Cheese curd cutting

- Heating and stirring

- Draining the whey

- Milling

- Heating, stretching, and kneading the cheese curd

- Extruding the mass of mozzarella cheese into the required shapes

- Salting

- Cold storing

- Packing and delivery

Role of automation in cheese making

Mechanization of cheese-making machines alone is not sufficient. To make cheese-making productive, mechanized cheese-making machines should be automated to minimize human labor. The human involvement is limited to the addition of starter culture and vegetarian rennet, overseeing the working of mechanized and automated cheese-making processes, and taking corrective action when necessary.

To realize the objective of continuous cheese making, each stage of cheese making is automized and amenable for linking one stage of cheese making to another stage using conveyors, pumps, etc.

Continuous cheese making

When all the cheese-making stages are mechanized and automated, they can be linked together to produce cheese continuously. This means the cheese milk fed at one end of the processing line undergoes different processes and comes out as mozzarella cheese at the other end.

The team of dairy technologists, engineers, and cheese makers worked together to mechanize and automate all cheese-making stages and link them with computer systems aided with artificial intelligence to create a continuous line for the production of many types of cheeses including mozzarella cheese.

Continuous mozzarella cheese manufacturing

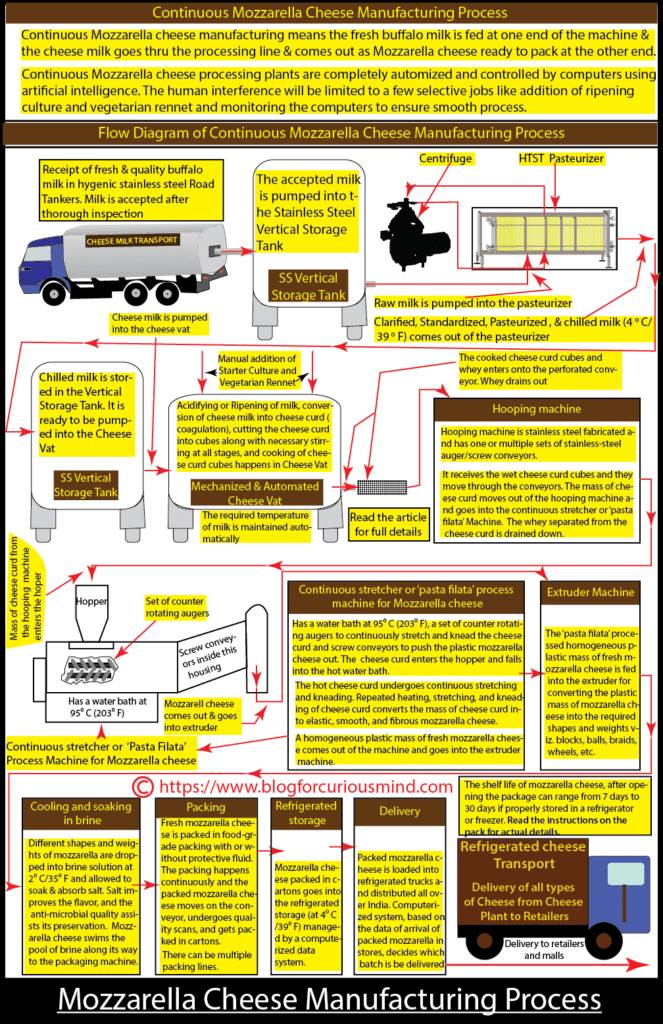

The processing of milk and its conversion to mozzarella cheese continuously is briefly explained below:

Milk reception

The fresh buffalo cheese milk arrives at the cheese dairy in insulated stainless steel road tankers. Samples of milk are taken from the tank and tested for different quality factors including odor, fat, protein content, and SNF; accepted milk is transferred to stainless steel storage tanks.

Filtration, standardization, and pasteurization of cheese milk

The milk stored in the storage tank is clarified, standardized, pasteurized, and chilled to ≤ 4⁰ C (39⁰ F); the chilled milk is stored in an SS storage tank.

- Pasteurization kills harmful pathogens and it is done by the HTST (High-temperature Short-time) process at 72⁰ C (162⁰ F) for 15 seconds.

- Standardization corrects the casein/fat ratio to the designed level

- Automated pasteurization plants with an output of 40000 LPH (liters per hour) and even more are available

Read the article ‘What is Pasteurization of Milk? How the Milk is Pasteurized’ to know more.

Cheese vat

The pasteurized cheese milk is pumped into the coagulation vat or cheese vat and it gets converted into cooked cheese curd cubes. Processes including heating the cheese milk ready for adding culture, adding vegetarian rennet, and cooking happens in the cheese vat.

The cheese milk travels through the following processes during its conversion in the vat:

- Adding ripening culture

- Adding vegetarian rennet

- Coagulation of cheese milk into semisolid curd and whey

- Cutting the cheese curd into around half-inch cubes

- Stirring when required

- Cooking cheese-curd

The addition of starter culture and vegetarian rennet is manual and other processes are mechanized with touch screen automatic controls. The cheese vat ensures the temperatures are checked and monitored for different processes in the cheese vat.

The cheese vat is of double-circle fabrication type with jackets and can be heated by circulating steam or hot water in the jackets. Cleaning can be done using the CIP (clean-in-place) system.

The cooked cheese-curd cubes and whey from the cheese vat is pushed onto a conveyor with drainage mesh and much of the whey is drained out. The wet cooked cheese cubes move on the conveyor into the inlet of the hooping machine.

Hooping machine

The hooping machine is fabricated from quality stainless steel; it has one or multiple sets of stainless steel auger conveyors. An auger is a rotating screw mechanism that can forcefully push the cheese curd ahead.

The hooping machine receives the wet cheese curd cubes and they move through one or multiple sets of auger conveyors. The cheese curd moving through the augers will lose some more whey and the whey is drained down. The mass of cheese curd moves out of the hooping machine and goes into the ‘pasta filata’ or stretching the curd process.

Continuous stretcher or ‘pasta filata’ process machine for Mozzarella cheese

This machine is fabricated from quality stainless steel.

This machine will have the facility for immersing the mass of cheese curd in a water bath maintained at 95⁰ C (203⁰ F) and continuously stretching and kneading the hot mass of cheese curd. The repeated heating, stretching, and kneading of the cheese curd converts the mass of cheese curd into elastic, smooth, and fibrous mozzarella cheese.

The cheese curd must be hot when it undergoes stretching and kneading. The process of stretching and kneading is like preparing the dough for baking bread.

A homogeneous plastic mass of fresh mozzarella cheese comes out of the machine and goes into the extruder machine.

Extruding the mozzarella cheese into different shapes and sizes

The ‘pasta filata’ processed homogeneous plastic mass of fresh mozzarella cheese is fed into the extruder for converting the plastic mass of mozzarella cheese into the required shapes and weights viz. blocks, balls, braids, wheels, etc.

Cooling and soaking in brine

The different shapes and weights of mozzarella cheese are dropped into the brine solution at 2⁰ C/35⁰ F and allowed to get soaked for sufficient time. The mozzarella cheese absorbs salt; the salt improves the flavor of mozzarella cheese and the anti-microbial quality assists its preservation. In a continuous process line of mozzarella cheese manufacturing, the mozzarella cheese swims in a pool of brine along its way to the packaging machine simultaneously absorbing the salt.

Packing

The fresh mozzarella cheese is packed in food-grade packing with or without protective fluid. The packing happens continuously and the packed mozzarella cheese moves on the conveyor, undergoes quality scans, and gets packed in cartons.

There can be multiple packing lines, one for each shape and weight.

Refrigerated storage

The mozzarella cheese packed in cartons is moved into the refrigerated storage managed by a computerized data system. The refrigerated store is maintained at 4⁰ C/39⁰ F.

Delivery

The packed mozzarella cheese is loaded into refrigerated trucks and distributed to retailers and malls all over India. The computerized system, based on the data on the arrival of packed mozzarella in stores, decides which batch has to be delivered.

The shelf life of mozzarella cheese, after opening the package can range from 7 days to 30 days if properly stored in a refrigerator or freezer. Read the instructions on the mozzarella pack for actual details.

You may view this YouTube video by Amul about their continuous cheese-making dairy units (continuous Mozzarella cheese-making is shown at the end).

You may view this, this, and this YouTube video showing mozzarella cheese-making machines.

Read the article ‘How Cheddar Cheese is Made’ to understand the traditional process of making cheese in detail.

Read the article ‘How Mozzarella Cheese Made in Factory’ to understand the traditional process of making Mozzarella cheese in detail.

More on mozzarella cheese

The process of continuous manufacturing of mozzarella cheese (discussed above) is one of the established methods. However, there can be variations to it, typically after the cooked cubes of cheese curd and whey come out of the cheese vat.

Mechanized cheddaring machine for mozzarella cheese

Stainless-steel mechanized cheddaring machine is used in continuous cheddar cheese manufacturing processing lines. However, a modified version of a mechanized cheddaring machine with 2 or three variable speed conveyors (instead of 4 conveyors for cheddar cheese) is offered by branded cheese machine manufacturers for the mozzarella cheese process line.

The modified version of the cheddaring machine for mozzarella cheese has stirrers and a milling cutter. The wet cubes of cheese curd are stirred to separate the whey, turned, fused, and milled into pieces before pushing it out. The whey is drained down. The milled cubes of cheese curd can be passed through a hooping machine before it undergoes a hot stretching process or may be directly loaded for a hot stretching process.

Aging

Even though, mozzarella cheese is made from fresh cheese curd, some manufacturers may place the shaped and brine salted mozzarella cheese in refrigerated stores for a short period of 4 days or for a longer period.

Conclusion

It is amazing to see how the raw buffalo cheese milk is standardized, pasteurized, ripened, and coagulated into cheese curd, and the cut cheese curd is cooked and converted into mozzarella cheese on a continuous line of machines. We should appreciate the technologists and cheese makers who work hard and deliver mozzarella cheese to cheese lovers. Hope this article could update your information on mozzarella cheese.

Note: Edits with authentic references are welcome.

References