Introduction

Puffed rice, or Murmura, in Hindi, is a popular snack food in India. Apart from India, puffed rice is produced and consumed in our neighboring countries Bangladesh and Nepal, and many Asian countries, viz. China, Japan, Taiwan, Korea, Philippines, Thailand, Malaysia, etc. Each country has its own local name for puffed rice. Puffed rice is commercially produced in the West and is part of many snack foods.

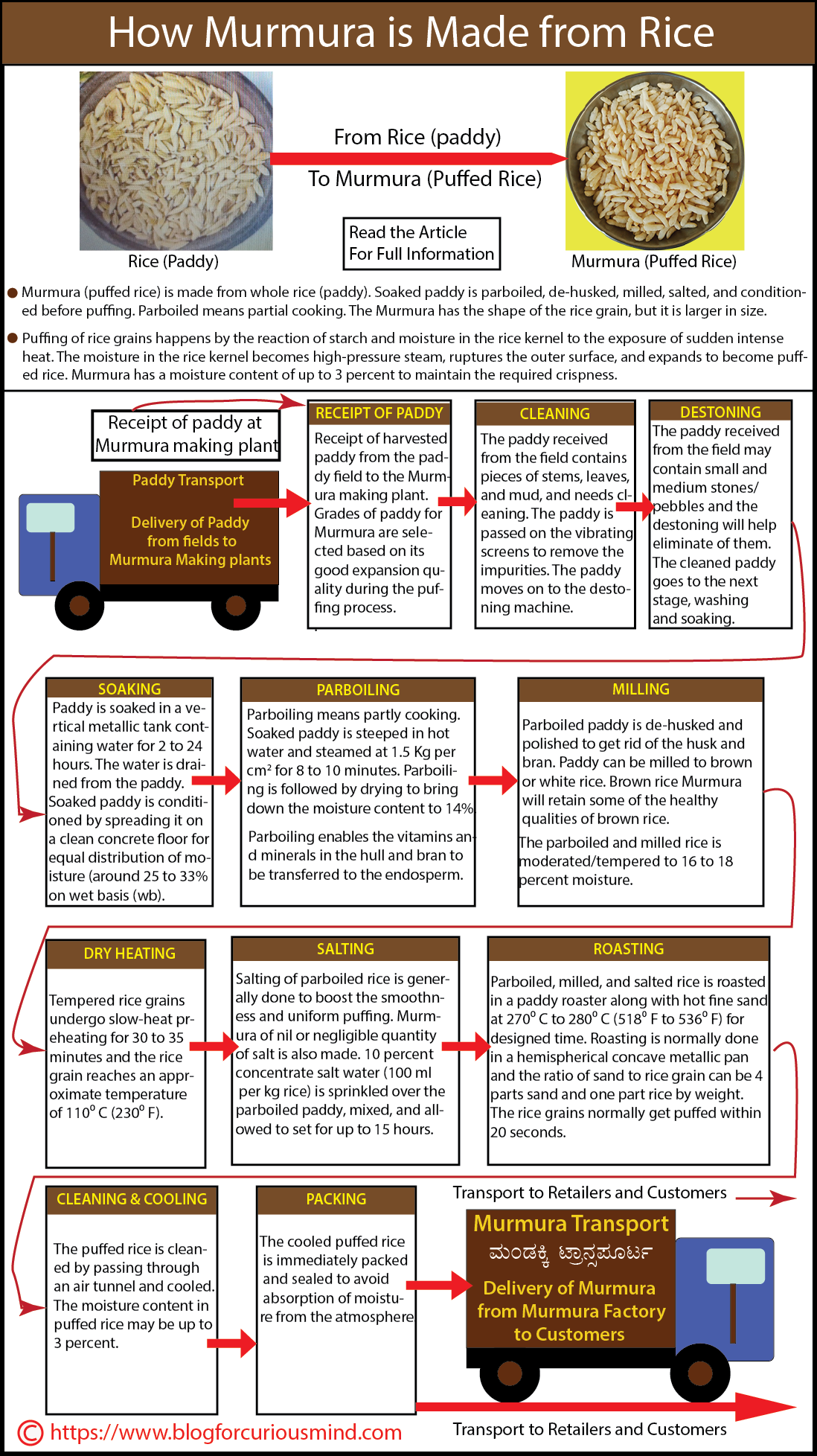

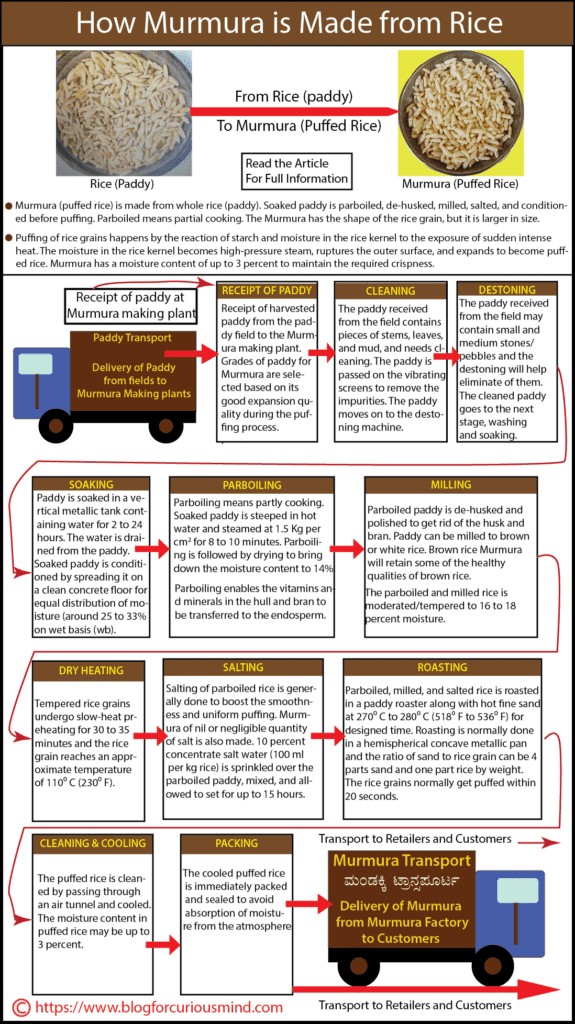

Murmura is made from paddy, which is whole rice. The soaked paddy is parboiled, de-husked, milled, and conditioned before puffing. Parboiled means partial cooking. The Murmura has the shape of the rice grain, but it is larger in size.

The method of producing puffed rice as an industry is credited to Alexander P. Anderson, an American inventor who stumbled upon the rice puffing process during his other research. He introduced the first rice puffing machine to the world in 1904.

India is the largest rice producer in the world, and it is said that 10% of rice produced in India is converted into products like Murmura, Poha, etc.

Puffed rice has a name in every Indian language. Some of the regional language names of puffed rice are listed below:

- Murmura in Hindi

- Puri and Mandakki in Kannada

- Pori in Tamil

- Pori in Malayalam

- Borugulu and Murmuralu in Telugu

- Kurmura in Marathi

- Mamra in Gujarati

- Pura in Panjabi

- Muri in Bengali

- Muri in Assamese

This article uses the name ‘Murmura’ for puffed rice since it is understood by many people. Do you want to know how Murmura is made from rice (paddy)? Keep reading the article to know!!

How Murmura (puffed rice) is made from rice

The puffing of rice grains happens by the reaction of starch and moisture in the rice kernel when exposed to sudden and intense heat. The moisture in the rice kernel becomes high-pressure steam, ruptures the outer surface, and expands to become puffed rice. The Murmura has a moisture content of up to 3 percent to maintain the required crispness.

The puffing of rice can be compared to the popping of corn. However, in contrast to corn, rice grains do not have moisture, so, they are parboiled and conditioned before being puffed.

The paddy/rice used for puffing is parboiled and conditioned to have the requisite moisture content. The moisture content of grain is normally established on a wet basis (wb). If you know the initial weight and final weight (after removing moisture) of the grain, you can calculate its moisture content.

Moisture content, wb = (Initial weight of the grain – Final weight of the grain) ÷ (Initial weight of the Grain) × 100 %.

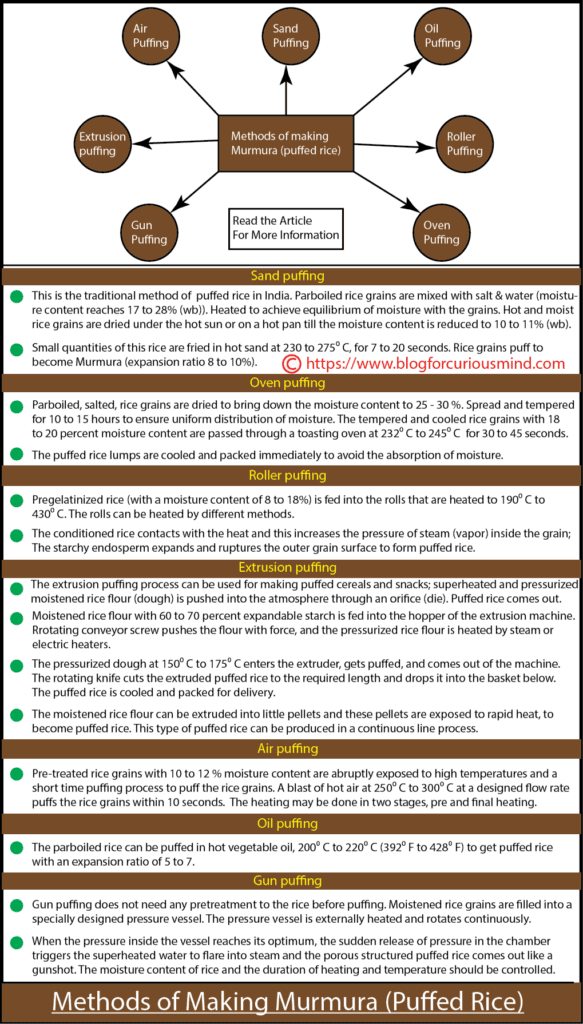

Rice can be puffed to Murmura by seven methods.

- Sand puffing

- Oven puffing

- Roller puffing

- Extrusion puffing

- Air puffing

- Oil puffing

- Gun puffing

Sand puffing

This is the traditional method of making puffed rice in India. The parboiled rice grains with a moisture content of around 11% are mixed with salt and minimal water sufficient to increase the moisture content to a range of 17 to 28% (wb). The wet rice grains are heated for up to 8 hours to achieve equilibrium of moisture with the grains. The hot and moist rice grains are dried under the hot sun or by heating in a metallic hemispherical concave pan with continuous stirring till the moisture content is reduced to 10 to 11% (wb).

Small quantities of this rice are roasted in hot sand at 230 to 275⁰ C (446⁰ F to 527⁰ F) for 7 to 20 seconds. This process puffs the rice into Murmura, and the expansion ratio can be 8 to 10 percent. It is a tiresome and low-productive process.

Oven puffing

The rice grains are pre-treated (pre-cooked) with salt, or salt and sugar syrup. The rice grains are dried to bring down the moisture content to 25 to 30 percent. The rice grain lumps are spread and tempered for 10 to 15 hours to ensure uniform distribution of moisture. The tempered and cooled rice grain lumps with 18 to 20 percent moisture content are passed through a toasting oven at 232⁰ C to 245⁰ C (450⁰ F to 473⁰ F) for 30 to 45 seconds.

The puffed rice is cooled and packed immediately to avoid the absorption of moisture.

Roller puffing

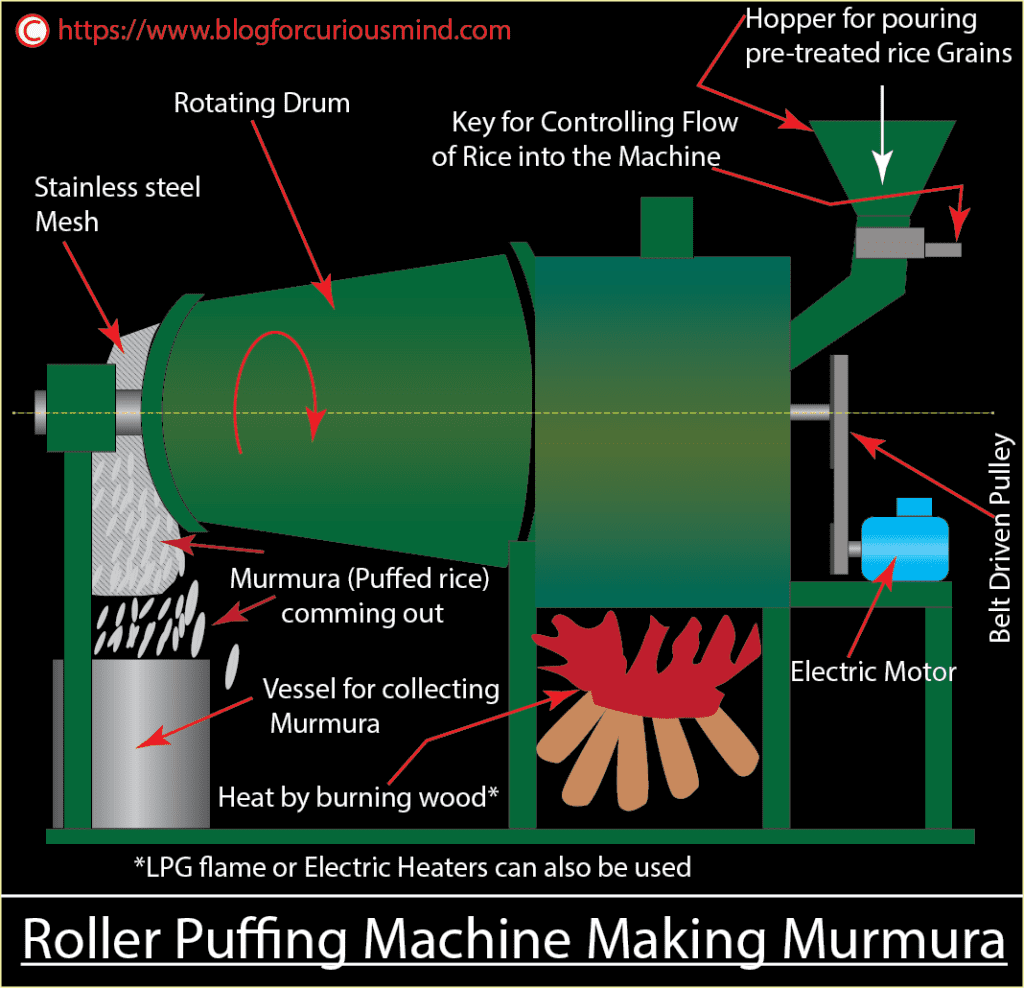

The rice should be pregelatinized before feeding into the roller puffing machine. Pregelatinizing is a process of de-husking, de-stoning, and cleaning of rice followed by soaking in brine solution and drying.

The pregelatinized rice (with a moisture content of 8 to 18%) is fed into the rolls that are heated to 190⁰ C to 430⁰ C (374⁰ F to 806⁰ F). The rolls can be heated by different methods.

The conditioned rice comes in contact with the heat and this increases the pressure of steam (vapor) inside the grain. The result is the outer surface of the rice rupture and the starchy endosperm expands to form puffed rice. The puffed rice with a moisture content of around 6 % comes out.

You may watch this and this YouTube video.

Extrusion puffing

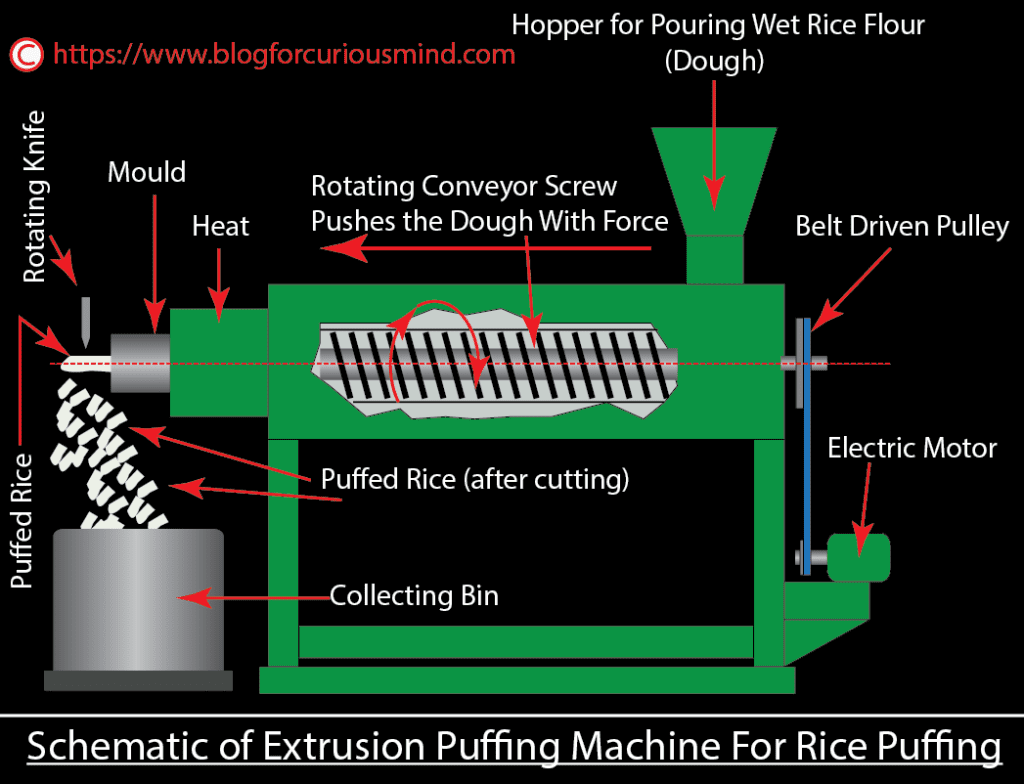

The extrusion puffing process can be used for making puffed cereals and snacks. Moistened rice flour with 60 to 70 percent expandable starch is fed into the hopper of the extrusion machine. Superheated and pressurized moistened rice flour (dough) is pushed into the atmosphere through an orifice (die).

The parts of a simple extrusion puffing machine are a hopper to feed the moistened rice floor, a barrel containing a single or double screw conveyor to push the wet rice flour with force, an electric motor to drive the screw, an extruder having one or multiple orifices of the required design, a rotating knife to cut the extruded puffed rice to the required length, a source of heat, and the support/body to hold the said parts.

The moistened rice flour (dough) is fed into the hopper, the rotating conveyor screw in the barrel pushes the flour with force, and the pressurized rice flour is heated by steam or electric heaters. The pressurized dough at 150⁰ C to 175⁰ C (302⁰ F to 347⁰ F) enters the extruder, gets puffed, and comes out of the machine. The rotating knife cuts the extruded puffed rice to the required length and drops it into the basket below. The puffed rice is cooled and packed for delivery.

Advantages of extrusion puffing:

- This process can be run continuously.

- Puffed rice products of different shapes and lengths are possible.

- The product can be fortified with added nutrients and minerals.

The disadvantage is the raw material required is moistened rice flour, you cannot feed rice grains directly.

The moistened rice flour (rice dough) can be extruded into little pellets. When these pellets are exposed to rapid heat, the pellets puff and become puffed rice. This type of puffed rice can be produced in a continuous line process.

You may watch this YouTube video.

Note: The video below shows a small motor-driven puffing machine that can be fed with moistened rice grains. The rice grains get crushed into the dough and come out through a mold as puffed rice. The heat generated by the crushed grains is sufficient for puffing.

You may watch the YouTube video.

Air puffing

This is a simple hazard-free, and fast puffing process. The pre-treated rice grains with 10 to 12 percent moisture content are abruptly exposed to high temperatures and a short time puffing process to puff the rice grains.

The major parts of an air puffing machine can be a hopper for feeding the grain, a heating chamber, a chamber for puffing, and others. A blast of hot air at 250⁰ C to 300⁰ C (482⁰ F to 572⁰ F) at a designed flow rate is used to heat and puff the rice grains. The puffing happens within 7 to 10 seconds. The heating may be done in two stages, pre-heating, and final heating. The expansion ratio of the puffed rice can be 8 to 10 percent.

Oil puffing

The parboiled rice can be puffed in hot vegetable oil, 200⁰ C to 220⁰ C (392⁰ F to 428⁰ F) to get puffed rice with an expansion ratio of 5 to 7.

Gun puffing

Unlike other rice puffing processes that need the rice to be parboiled before puffing, gun puffing does not need any pretreatment to the rice before puffing. Moistened rice grains are filled into a specially designed pressure vessel. The pressure vessel is externally heated and rotates continuously. The heating can be electric or by an LPG flame. When the pressure inside the vessel reaches its optimum, the sudden release of pressure in the chamber triggers the superheated water to flare into steam and the porous structured puffed rice comes out like a gunshot. The moisture content of rice and the duration of heating and temperature should be controlled.

You may watch this and this YouTube video.

Step-by-step process of making Murmura by sand puffing

Step 1: Paddy can be sourced directly from farmers who harvest paddy or dealers. The Murmura manufacturer selects the grade of paddy suitable for puffed rice and arranges its transport to the Murmura factory.

Step 2 Cleaning: The paddy may contain pieces of leaves, stems, small stones, and mud which must be cleaned. The paddy moves on a vibrating screen that removes pieces of leaves, stems, dirt, and mud. The paddy is passed on to its next process de-stoning.

Step 3, De-stoning: The paddy may have small and medium-sized stones and pebbles and this is removed by the de-stoning machine.

Step-4 Soaking: The paddy is soaked in a tank containing water and the soaking period can be 2 to 24 hours. Large manufacturers of Murmura use vertical metallic tanks with arrangements for feeding the paddy into the tank and taking it out after processing. The water is drained from the paddy.

The soaked paddy is conditioned by spreading it on a clean concrete floor and this helps equal distribution of moisture in the paddy. Depending on the process of soaking and conditioning and the climate, the moisture content of the conditioned paddy will be 25 to 33 percent.

Manufacturers do not use hot water for soaking, since it can give color to the Murmura.

Step-5 Parboiling: Parboiling means partly cooking. In parboiling, the soaked paddy is steeped in hot water and steamed at 1.5 Kg per cm2 for 8 to 10 minutes. The extent of parboiling is determined based on the moisture content of the soaked paddy. The parboiling process is followed by drying to bring down the moisture content to 14% (approximately).

Parboiling enables the vitamins and minerals in the hull and bran to be transferred to the endosperm.

Step-6 Milling: The parboiled paddy is de-husked and polished to get rid of the husk and bran. Depending on the need the de-husking and polishing operations are carried out to obtain brown rice or white rice. The Murmura made from brown rice will retain some of the healthy qualities of brown rice. The moisture content at this stage may be 14 to 15 percent.

The parboiled and milled rice is moderated to accomplish the moisture content in the range of 16 to 18 percent.

Step-7 Dry heating: The tempered rice grains undergo slow-heat preheating for 30 to 35 minutes and the rice grain reaches an approximate temperature of 110⁰ C (230⁰ F).

Step-8 Salting: Salting of parboiled rice is generally done to boost the smoothness and uniform puffing. However, Murmura of nil or negligible quantity of salt is also made. A 10 percent concentrate salt solution (salt water) is prepared and sprinkled over the parboiled paddy. The salted parboiled paddy is mixed and allowed to set for up to 15 hours. The quantity of salt solution used maybe 100 ml for each kg of parboiled and milled rice.

Step-9 Roasting:

The parboiled, milled, and salted rice is roasted in a paddy roaster along with hot fine sand maintained at a temperature of 270⁰ C to 280⁰ C (518⁰ F to 536⁰ F) and the exposure time can be fixed as established by experience.

The roasting is normally done in a hemispherical concave metallic pan and the ratio of sand to rice grain can be 4 parts sand and one part rice by weight. The rice grains normally get puffed within 20 seconds. Continuous stirring is done during roasting.

Step-10 Cleaning and cooling: The puffed rice is cleaned by passing through an air tunnel and cooled. The moisture content in puffed rice may be up to 3 percent.

Step-11 Packing: The cooled puffed rice is immediately packed and sealed to avoid absorption of moisture from the atmosphere.

You may watch this YouTube video.

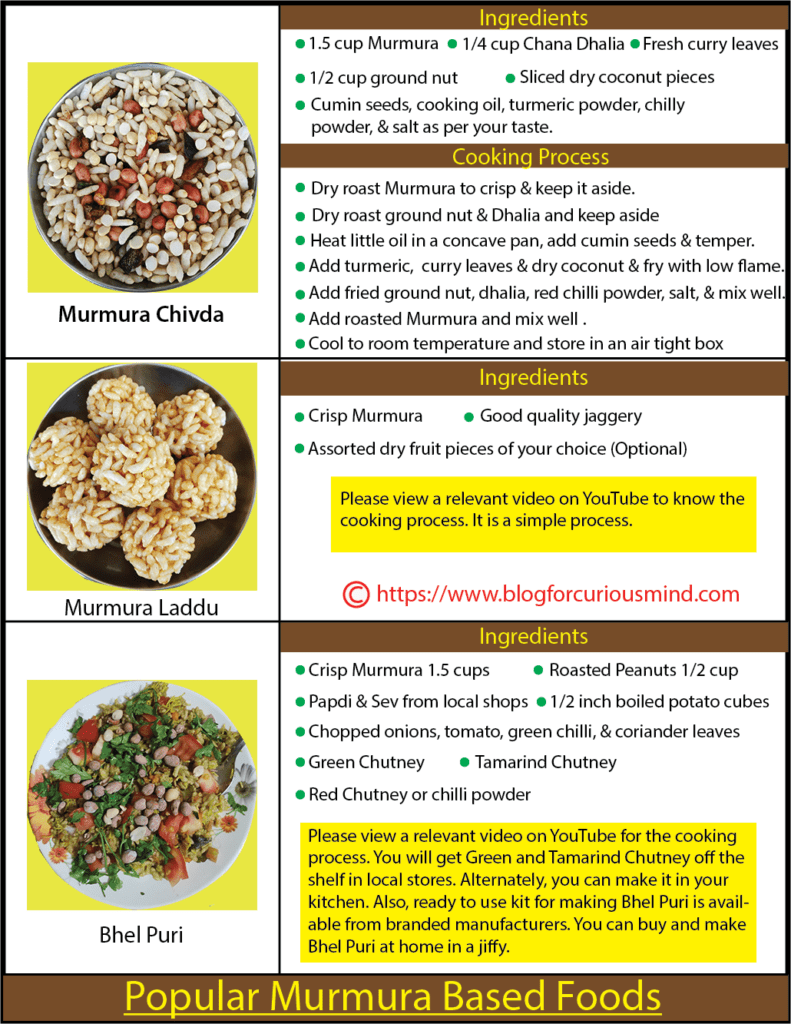

Murmura based foods

Some of the popular snacks made from Murmura are Bhel, Jhal Muri (Bengali version of Bhel), Jaggery mixed Murmura sweet balls (Ladoo), Churmuri, Murmura Chivda, Namkeen and Murmura mix, Murmura Chikki, etc. In parts of Karnataka (Mysuru, Bengaluru, etc.) a mix of crisp Murmura and Chana Daliya (Roasted Chickpea Bengal gram) is an instant snack done in seconds and liked by children.

Murmura is used as a street food ingredient in most Indian cities, and towns. You can enjoy tasty Bhel, churmuri, Jhal Muri, and other Murmura-based snacks from the street food carts.

Conclusion

You all had tasted Murmura and Murmura-based foods like Bhel, Churmuri, Jal Muri, etc. Now you know how Murmura is produced. We must salute the people who sweat hard to bring tasty Murmura to its consumers.

You may want to read the following articles:

Nutrients and Vitamins in Cornflakes

How Ragi Huri Hittu or Popped Ragi Powder is Made

How Poha is Made from Rice (paddy).

How Rice is Grown and Harvested in India.

What is Sabudana and how it is made in India?

References

https://en.wikipedia.org/wiki/Puffed_rice

https://niftem.ac.in/newsite/pmfme/wp-content/uploads/2022/07/Rice-Based-Product-Handbook.pdf

https://niftem.ac.in/newsite/pmfme/wp-content/uploads/2022/07/Rice-based-product-Process-PPT.pdf