Introduction

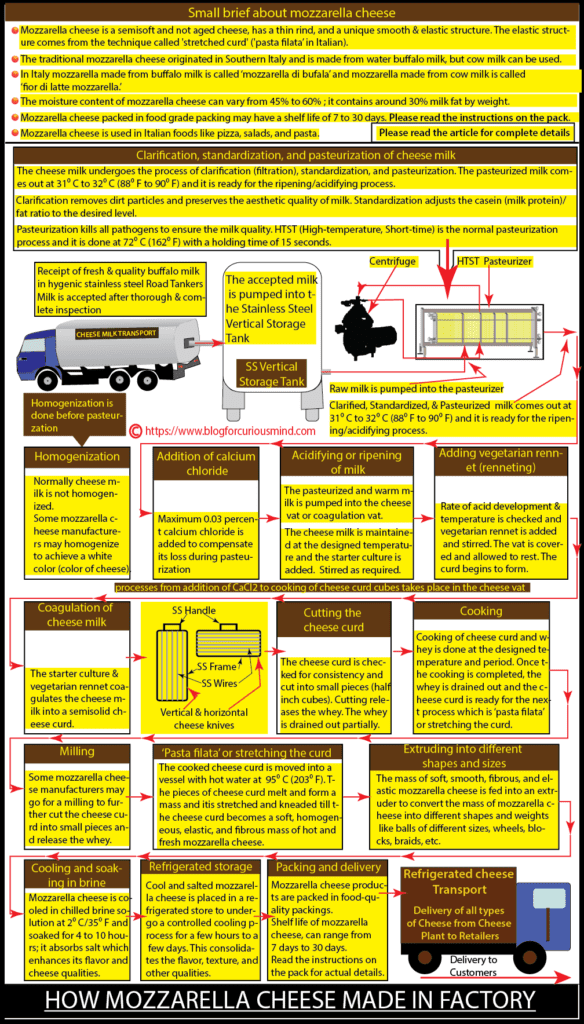

Mozzarella cheese is a semisoft and not aged cheese originating from Southern Italy. Traditional Mozzarella cheese is made from water buffalo milk (bred in Italy), cow milk can also be used. After cheddar cheese, mozzarella cheese is the second most popular cheese worldwide.

The elastic structure of mozzarella cheese and its uniform meltability make it a super choice for pizza making.

We shall discuss how mozzarella cheese is made in factory in this article.

Small brief about mozzarella cheese

The traditional mozzarella cheese originated in Southern Italy and is made from water buffalo milk, but cow milk can also be used. Since buffaloes are bred only in some parts of the world, cow milk is largely used in manufacturing mozzarella cheese. Mozzarella cheese made in India uses both buffalo and cow milk.

In Italy mozzarella cheese made from buffalo milk is called ‘mozzarella di bufala’ and mozzarella made from cow milk is called ‘fior di latte mozzarella.’

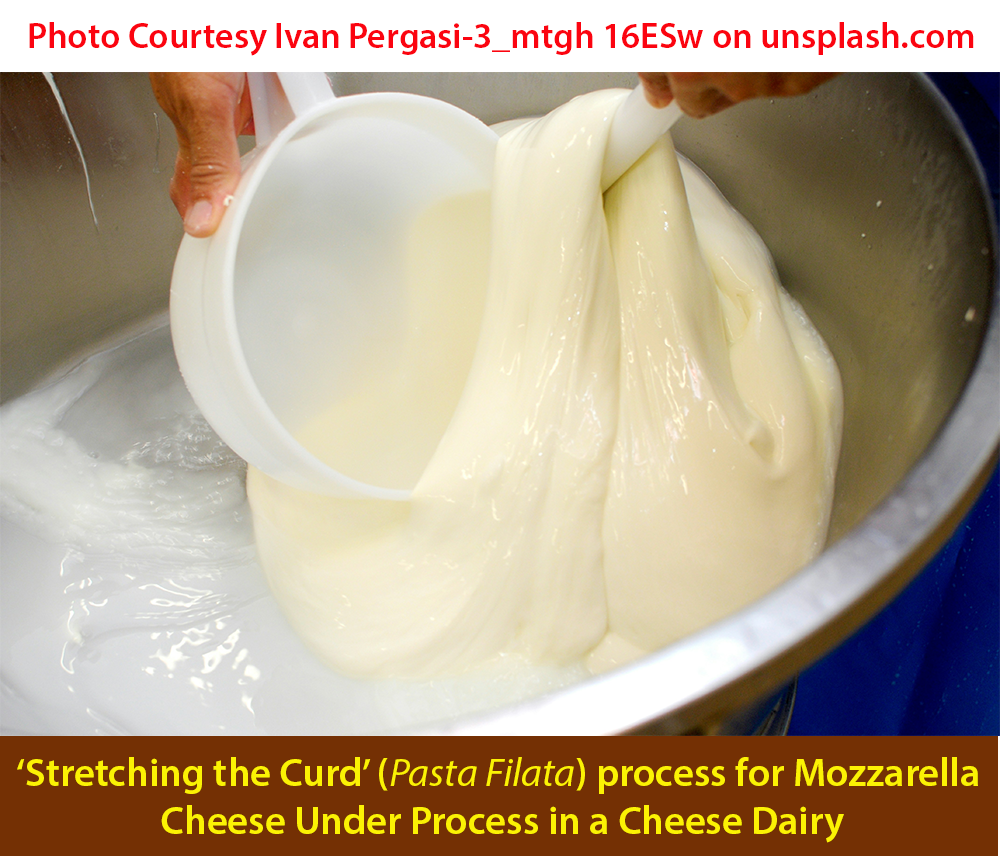

Mozzarella cheese is a semisoft and not aged cheese, has a thin rind, and a unique elastic structure. The elastic structure comes from the technique called ‘stretched curd’ (‘pasta filata’ in Italian) adopted during mozzarella cheese making.

As per the manufacturing experts of mozzarella cheese in Italy, the process of ‘Pasta filata‘ or stretching the curd is explained as “the cheese maker stretches the hot cheese curd, folds, and kneads with hands, just like kneading the dough for making bread. Heating the cheese curd in hot water and stretching, folding, and kneading continues till the cheese becomes soft, smooth, fibrous, and elastic.” However, this process was mechanized long ago.

In some places, mozzarella cheese is made from sheep and goat milk. Some types of mozzarella cheese are given TSG (Traditional Specialties Guaranteed) and PDO (Protected Designation of Origin) certifications.

The moisture content of mozzarella cheese can vary from 45% to 60% depending on the type of mozzarella and the milk used to make it (mozzarella cheese is made from whole buffalo milk, whole cow milk, or partially skimmed milk). Mozzarella cheese contains around 30% milk fat by weight.

Mozzarella cheese made from buffalo milk is more nutritious than mozzarella cheese made from cow milk. Unlike cheddar cheese, mozzarella cheese is fresh and not aged. The high-fat content (6.1%) of buffalo milk gives mozzarella cheese a typical flavor and creamy texture.

Mozzarella cheese is used in Italian foods like pizza, salads, and pasta. The normal color of traditional mozzarella cheese is white porcelain and has smooth elastic structure. However, the milk obtained from certain breeds of cows may have a yellow tint and mozzarella cheese made from such milk can have a yellow tint. Additives may be added to such milk to make the color of mozzarella cheese white.

Mozzarella cheese packed in food quality packing may have a shelf life of 7 to 30 days after opening the pack if it is stored in a refrigerator or freezer. Please read the instructions on the pack and follow them.

Mozzarella cheese manufacturing process

The traditional manufacturing of mozzarella cheese uses water buffalo whole milk and has the following sequence of processes. But cow milk can also be used. Since buffaloes are bred only in a few countries, most of the mozzarella cheese made worldwide today is from cow’s milk.

- Receipt of raw buffalo milk in stainless steel tankers and its thorough inspection

- Clarification

- Standardization of milk

- Pasteurization of milk

- Addition of calcium chloride

- Acidifying or ripening of milk (adding starter culture)

- Adding vegetarian rennet (renneting)

- Coagulation of milk or conversion of milk into cheese curd and whey

- Cutting the coagulated curd into half-inch cubes, and partial draining of the whey

- Cooking

- Draining the whey

- ‘Pasta filata’ or stretching the curd

- Extruding the mozzarella cheese into different shapes and sizes

- Cooling and soaking in brine (20% salt in water)

- Refrigerated storage

- Packing and delivery

The processes from the addition of calcium chloride to cooking can take place in the cheese vat.

Step-by-step process of manufacturing mozzarella cheese

Step-by-step process of manufacturing mozzarella cheese

Receipt of milk

Fresh and good quality buffalo milk is the foundation for manufacturing quality and tasty mozzarella cheese. The milk should be fresh and have a good flavor, look good, and other required qualities. Milk received in every tanker should be tested for vital parameters including fat and casein by making a sampling test. The accepted milk is pumped into an insulated storage tank. Let us call this milk cheese milk.

Raw buffalo milk used for mozzarella cheese may have 6.1% fat and 3.5% to 4.5% protein.

Clarification, standardization, and pasteurization of cheese milk

The cheese milk undergoes the process of clarification (filtration), standardization, and pasteurization. The pasteurized milk comes out at 31⁰ C to 32⁰ C (88⁰ F to 90⁰ F) and it is ready for the ripening/acidifying process.

- Clarification removes dirt particles and preserves the aesthetic quality of milk.

- Standardization adjusts the casein (milk protein)/fat ratio to the desired level for optimizing the yield of mozzarella cheese per kilogram of cheese milk fat. The desired C/F ratio for mozzarella cheese is 0.9 to 1.2 depending on other required parameters like FDB % (fat-on-dry basis). Standardization of cheese milk to maintain the casein fat ratio gives better yield and improved body and texture.

- Pasteurization kills all pathogens to ensure the milk quality. HTST (High-temperature Short-time) is the normal pasteurization process and it is done at 72⁰ C (162⁰ F) with a holding time of 15 seconds.

All the above processes happen in a continuous loop.

Read the article ‘What is Pasteurization of Milk? How the Milk is Pasteurized’ to know more.

Homogenization

In the normal course, cheese milk is not homogenized. However, some mozzarella cheese manufacturers may homogenize the cheese milk to achieve a white color mozzarella cheese.

Read the article ‘What is Homogenized Milk? How Milk is Homogenized?‘ to know more.

Addition of calcium chloride

The heating cycle of pasteurization may lead to precipitation loss of calcium salts in cheese milk and it is made up by adding a maximum of 0.03 percent calcium chloride. This will improve the rennet action and form good cheese curd.

Acidifying or ripening of milk

The pasteurized and warm milk is pumped into the cheese vat or coagulation vat. The cheese vat may be rectangular or circular and its capacity can range from 1000 liters and up to 90000 liters or more. The cheese vat has stirrers to mix the cheese milk, heating jackets to heat the cheese milk, cheese curd knives, and a draining facility to drain the whey. The cheese vat can be covered when required.

The cheese milk is maintained at the designed temperature for ripening and the required amount of starter culture (lactic culture with beneficial bacteria) is added to the cheese milk. The starter culture ferments the milk sugar (lactose) into lactic acid. Cheese milk is stirred as required.

Adding vegetarian rennet (renneting)

The cheese milk is checked to ensure the rate of acid development and temperature before adding vegetarian rennet to the cheese milk. The renneting temperature is around 34⁰ C (93⁰ F) but depends on the type of milk and rennet. Diluted vegetarian rennet is added to the cheese milk and stirred as required. The vat is covered and allowed to rest. The curd begins to form as the caseins in the milk group together and solidify.

Coagulation of cheese milk

The addition of starter culture and vegetarian rennet coagulates the cheese milk into a semisolid cheese curd. Coagulation is the beginning of the transformation of cheese milk into different cheeses including mozzarella cheese. The consistency of cheese curd is checked to ensure it is ready for the cutting process.

Cutting the cheese curd

The cheese curd is checked for consistency and it is cut into small pieces (half-inch cubes) using vertical and horizontal knives. The cutting is manual for small vats and mechanized for large vats. Cutting the cheese curd into small cubes releases the whey and is an important step in determining the final texture of mozzarella cheese.

The cheese curd is separated from the liquid whey and the whey is drained out partially. The mass of cheese curd moves into the next process, cooking.

Cooking

Cooking of cheese curd and whey is done at the designed temperature and period. Once the cooking is completed, the whey is drained out and the cheese curd is ready for the next process which is ‘pasta filata’ or stretching the curd.

Milling

Some mozzarella cheese manufacturers may pass the cheese curd for a milling process to further cut the cheese curd into small pieces and release the whey.

‘Pasta filata’ or stretching the curd

The cooked cheese curd is moved into a vessel with hot water maintained at around 95⁰ C (203⁰ F). The cubes of cheese curd melt and form a mass and this mass of cheese is stretched and kneaded. Stretching and kneading of cheese curd should be done repeatedly till the cheese curd becomes elastic, smooth, and fibrous.

When the volume of mozzarella cheese production is small, the stretching and kneading are done manually, but the process is mechanized for handling large quantities. It is important to maintain the temperature of hot water and to ensure the cheese curd is hot when stretched and kneaded. The stretching and kneading process can be compared to preparing the dough for baking bread.

Heating, kneading, and stretching the cheese curd continues till the cheese curd is converted into a soft, homogeneous, elastic, and fibrous mass of hot and fresh mozzarella cheese. Repeated heating and kneading will be necessary to achieve the required structure of mozzarella cheese.

Extruding the mozzarella cheese into different shapes and sizes

The mass of soft, smooth, fibrous, and elastic mozzarella cheese is fed into an extruder to convert the mass of mozzarella cheese into different shapes and weights like balls of different sizes, wheels, blocks, braids, etc.

For small batches, shaping of mozzarella cheese can be done manually.

Cooling and soaking in brine

The mozzarella cheese of different shapes is quickly cooled in the chilled brine solution maintained at 2⁰ C/35⁰ F and soaked in it for 4 to 10 hours; the mozzarella cheese absorbs salt, and the salt enhances its flavor and helps its preservation as an anti-microbial agent. This also helps preserve the shape and mozzarella cheese qualities.

Refrigerated storage

The cool and salted mozzarella cheese of different shapes is placed in a refrigerated store. The mozzarella cheese of different shapes undergoes a refrigerated and controlled cooling process in the store and is stored for a few hours to a few days depending on the type of mozzarella cheese. The cooling period consolidates the flavor, texture, and other qualities acquired during cheese processing.

Packing and delivery

The mozzarella cheese products are packed in a food-quality pack to keep the mozzarella fresh and moist. The shelf life of mozzarella cheese, after opening the package can range from 7 days to 30 days if properly stored in a refrigerator or freezer. Read the instructions on the mozzarella pack for actual details.

The packed mozzarella cheese is transported in refrigerated trucks to retailers and malls to reach the customers.

Mozzarella cheese is made in India by Amul and many other dairies.

Read the article ‘How Cheddar Cheese is Made’ to understand the traditional process of making cheddar cheese in detail. And also, ‘Cheddar Cheese Manufacturing process‘.

You may view this and this YouTube video on how mozzarella cheese is made.

More on mozzarella cheese

Adding a food-quality emulsifier (an emulsifier is an additive used for stabilizing processed foods) to the mozzarella cheese after it is heated and stretched (before forming it into shapes) may alter the product characteristics significantly.

Conclusion

The journey from raw buffalo milk to delicious mozzarella cheese is remarkable! I have no doubt that all of you cheese lovers will agree with me. Hope, this article helps you appreciate the efforts taken by dairy technologists, engineers, and importantly the cheesemakers who work hard to bring the tasty mozzarella cheese to your dining table.

Note: Edits with authentic references are welcome.

References

https://en.wikipedia.org/wiki/Mozzarella

https://www.foodunfolded.com/article/mozzarella-cheese-how-its-made

https://egyankosh.ac.in/bitstream/123456789/9598/1/Unit-6.pdf