Introduction

Cheese is one of the oldest foods known to mankind and it was part of the Roman and Greek diet more than 2500 years ago. Till the 1850s, cheese was made in the ‘Farm House‘ on a small scale. The introduction of cheese production on a large scale started between 1860 and 1880.

However, cheese was not popular amongst Indians and cheese manufacture did not develop in India till the late 1960s. The main reason could be cheese was traditionally made using animal rennet sourced from calf and most Indians (Hindus, Jains, and others) worship cows and consider cow slaughter as a serious sin.

However, with the introduction of plant-based rennet or vegetarian coagulating enzymes and microbial rennet (microbial rennet is not sourced from animals, and hence can be consumed by vegetarians), cheese is slowly gaining popularity in India. Indian dairies produce cheese using vegetarian coagulating enzymes (vegetarian rennet) or microbial rennet only. Still, butter, paneer, and ghee are the favorites and most Indians prefer them over cheese. Cheese is popular in pizza, pasta, sandwiches, soups, and similar products.

Please read the article on rennet to know more about it.

In India, cheese is a product made from cow or buffalo milk in line with products like butter, ghee, and milk powder and all these products work as the balance wheel of the dairy industry. The primary purpose of a milk dairy in India is to sell healthy and affordable processed milk to the public; still, it is not a secret that producing butter, ghee, milk powder, and cheese is more profitable than selling processed milk. There are government stipulations to ensure that a dairy will not overindulge in producing profitable products by neglecting the supply of processed milk.

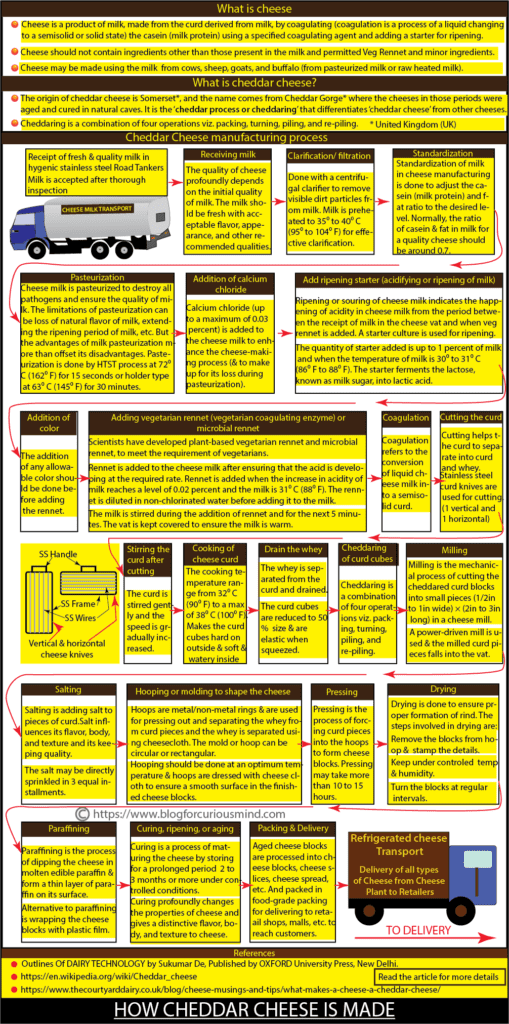

What is cheese

According to the PFA (Prevention of Adulteration Act enacted by the Parliament of India), cheese is produced from the curd derived from milk by coagulating milk using a specified coagulating agent and under the influence of a culture containing harmless bacteria. Cheese should not contain ingredients other than those present in the milk and permitted coagulating agent and minor ingredients (permitted under PFA).

Cheese may be made using the milk obtained from cows, sheep, goats, and buffalo. Cheese can be made from pasteurized milk or raw heated milk.

You can define cheese as a product of milk, made from the curd derived from milk, by coagulating (coagulation is a process of a liquid changing to a semisolid or solid state) the casein (milk protein) using a specified coagulating agent and adding a starter for ripening.

When the milk is coagulated (becomes semisolid), the liquid whey is separated by draining, cutting, cooking, and pressing into the molds. The shaped cheese is taken out from the mold and it is ripened and seasoned under a controlled and hygienic atmosphere (temperature and humidity) for 3 to 6 months or more. The ripened and seasoned cheese is further processed into different products and made ready for sale.

Cheese can be generally classified as acid and rennet cheese. Acid cheese refers to the cheese made by adding acid (like vinegar or lactic acid) to the milk to make a coagulation process. Fresh cheese or cream cheese are made by direct addition of acid. Cheese like cheddar cheese uses a vegetarian rennet or vegetarian coagulation enzyme (in addition to the acid or starter) to coagulate the milk. Flavor ingredients like herbs and spices may be added to the cheese.

Small brief about cheese

There are more than 100 varieties of cheese made in multiple countries, each differing in size, color, hardness, flavor, and taste. However, no matter in which country the cheese is made, the basic process of cheese manufacturing includes the following characteristics:

- Cheese is made using the milk obtained from cows, sheep, goats, or buffalo.

- Souring or ripening of milk.

- Coagulation of milk by rennet or a vegetarian coagulating enzyme (vegetarian rennet) or microbial rennet.

- Breaking or cutting the coagulation to release the whey.

- After the whey is drained, the curd is consolidated and allowed to mat together.

- Curing or maturing the green cheese by shaping in hoops, or molds.

The above are the essential characteristics of cheese manufacturing in any country. Still, the final product can differ from country to country or manufacturer to manufacturer due to the following factors.

- Type and quality of milk used.

- Type of souring organisms added and the extent of souring.

- Temperature of milk when rennet is added.

- Cooking or heating of the curd in the whey.

- The procedure used for cutting and breaking of curd and its degree of fineness.

- The method of treating or processing curd after the whey is separated from it.

- Milling and salting of the curd before it is shaped in a hoop or mold.

- Amount of pressure applied on the green cheese to shape it in the hoop or mold.

- Process followed for curing or maturing the cheese blocks including temperature, relative humidity, and curing period.

- Special treatment is given to the cheese like dipping in the brain (salt water), surface treatment, etc.

The above factors are under the control of the cheese manufacturer and can vary from manufacturer to manufacturer. All these factors have an influence on the physical, chemical, and microbiological change that takes place as the cheese is produced and processed. So, the flavor, color, and type of each brand of cheese may not be the same.

Cow milk is the largely used milk for cheese production since it contains an optimum quantity of fat and casein (milk protein). Popular cheeses like cheddar and other cheeses like Gowda are made from cow milk.

The high lactose content in sheep milk makes it a good choice for cheese making and, in some places, it is used for making feta, Manchego, and other type of cheeses.

Goat milk is used for making cheeses like French Bucheron and it has a distinct flavour.

Buffalo milk is good for making mozzarella cheese. But, most mozzarella cheese is made from cow milk.

Based on the moisture content in cheese, cheese can be categorized as under:

- Very hard (less than 25 percent moisture).

- Hard (25 to 36 percent moisture).

- Semi-hard (36 to 40 percent moisture).

- Soft (40 percent moisture).

Cheese has good food and nutrient value.

- It is an admirable source of milk protein.

- Rich in calcium and phosphorous.

- Good sources of vitamins A, D, E, and K. These are known as soluble vitamins.

- High calories.

- Pleasant to taste and digestible.

What is cheddar cheese?

Cheddar cheese is so far the best-known and popular cheese made and consumed in most parts of the world. More than half of the cheese sold in the UK is cheddar cheese. Cheddar cheese has variants in many countries including the USA, Australia, New Zealand, Canada, and India. The variant of India is called Indian cheddar.

One thing that controls the cheddar cheese is it is a hard, firm, and dry cheese with a moisture content of less than 39 percent. It is the ‘cheddar process’ that differentiates ‘cheddar cheese’ from other cheeses. However, all manufacturers of cheddar cheese may not follow the same ‘cheddar process.’

The origin of cheddar cheese is Somerset (UK), and the name comes from Cheddar Gorge (UK) where the cheeses in those periods were aged and cured in natural caves. These cheeses were sold to the tourists who visited the Gorge. There are stories about this dating back to the 16th century, but there are no solid proofs. The cheddar cheese as it is manufactured now may date back to the 1800s. As of now, cheddar cheese does not have a PDO (Protected Designation of Origin).

Cheddar cheese is powder salted, unlike cheese like mozzarella which is brine salted.

You may view this YouTube video.

Cheddar Cheese manufacturing process

It is important to maintain a high level of hygiene in a cheese manufacturing plant. All the equipment and accessories used in the plant should be sterilized and cleaned as per the recommended procedure. Normally CIP (Clean in Place) system is adopted. Milk must be received and handled in hygienically cleaned and sanitized equipment.

Steps involved in the Cheddar Cheese manufacturing process

Receiving of milk

The quality of cheese profoundly depends on the initial quality of milk used to make it, including the composition of milk (specifically the fat, protein, and calcium). The milk should be fresh with acceptable flavor, appearance, and other recommended qualities. Milk should be properly inspected for quality at the time of receipt. A sampling test is conducted to determine the contents of the milk viz. fat, casein, etc.

Clarification or filtration of milk

This is usually done with a centrifugal clarifier and the purpose is to remove visible dirt particles from milk to ensure the aesthetic quality of the cheese produced. Milk is preheated to 35⁰ to 40⁰ centigrade (95⁰ to 104⁰ Fahrenheit) for effective clarification.

Standardization of milk

The purpose of standardization of milk in cheese manufacturing is to adjust the casein (milk protein) and fat ratio to the desired level. The objective of standardization is to regulate the fat content in cheese and to optimize the maximum amount of cheese produced for every kilogram of fat in the cheese milk. Normally, the ratio of casein & fat in milk for a quality cheese should be around 0.7. Many cheese manufacturers may not include standardization of milk in cheese manufacturing.

Pasteurization

It is essential to pasteurize the cheese milk to destroy all pathogens and ensure the quality of milk. The limitations or drawbacks of pasteurization can be loss of natural flavor of milk, extending the ripening period of milk, etc. However, the advantages of milk pasteurization more than offset its disadvantages. Pasteurization is done by HTST (High-Temperature Short-Time) process at 72⁰ Centigrade (162⁰ Fahrenheit) for 15 seconds or holder type at 63⁰ Centigrade (145⁰ Fahrenheit) for 30 minutes. The pasteurized milk is cooled to 31⁰ centigrade to 32⁰ centigrade (88⁰ F to 90⁰ F) to make it ready for ripening.

Till the 1940s, the traditional cheese was produced from raw milk. Post-1940s, pasteurized milk or heat-treated milk is used for the production of cheese since the advantages of pasteurization outweigh its disadvantages.

Homogenization

Homogenization of cheese milk has advantages like reduced fat losses in whey, but the disadvantages like the formation of a softer curd overweighs against the advantages. Hence, cheese milk is normally not homogenized.

Addition of calcium chloride

The heating and cooling of the cheese milk may result in the precipitation of a portion of calcium salts in it. Calcium chloride (up to a maximum of 0.03 percent) is added to the cheese milk to enhance the cheese-making process. Lower calcium content in cheese milk may result in slower rennet action and a weak curd and the addition of calcium chloride overcomes this situation.

Addition of ripening starter (acidifying or ripening of milk)

Ripening or souring of cheese milk indicates the happening of acidity in cheese milk from the period between the receipt of milk in the cheese vat and when rennet is added. A starter culture is used for ripening the cheese milk. A starter culture is a certain group of beneficial bacteria and it is specific for each type of cheese. This process is also known as acidifying the milk. Ripening drops the pH value of milk and milk starts developing the cheese flavor.

Starter has an important role in cheese manufacturing and a bad starter can lead to a bad quality cheese. The starter used in cheese manufacturing depends on the type of cheese produced. The starter used for ‘cheddar’ cheese will not be the same as used for normal cheese.

A starter is normally added before the complete milk is received in the vat. The quantity of starter added is up to 1 percent of milk and when the temperature of milk is 30⁰ centigrade to 31⁰ centigrade (86⁰ F to 88⁰ F). Ripening of cheese milk helps in achieving the desirable quality of curd. The ripeness of the cheese milk can be tested. The starter ferments the lactose, known as milk sugar, into lactic acid.

Addition of color

The addition of any allowable color should be done before adding the rennet.

Adding vegetarian rennet (vegetarian coagulating enzyme) or microbial rennet

Adding rennet is called renneting or setting. This is also known as the curdling process. Rennet is an enzyme prepared by the substance obtained from the stomach lining of a young calf. Young calf produces rennet enzyme in their stomach for digesting their mother’s milk.

However, scientists have developed plant-based vegetarian rennet and microbial rennet, to meet the requirement of vegetarians.

The rennet used in Indian cheese manufacturing is plant-based and is known as a vegetarian coagulating agent. Microbial rennet (microbial rennet is not sourced from animals, hence can be consumed by vegetarians) is used for cheddar cheese.

Rennet is added to the cheese milk after ensuring that the acid is developing at the required rate. Rennet is added when the increase in acidity of milk reaches a level of 0.02 percent (from its initial level) and the temperature of the milk is 31⁰ centigrade (88⁰ Fahrenheit). The rennet is diluted in non-chlorinated water before adding it to the milk.

The amount of rennet added depends on the power of the rennet, milk temperature, acidity of milk, and composition of milk. The milk is stirred meticulously during the addition of rennet and for the next 5 minutes to ensure complete mixing. The vat is kept covered to ensure the milk is warm.

Coagulation

Coagulation refers to the conversion of liquid cheese milk into a semisolid curd. The coagulation can be checked by dipping a stainless-steel spatula and withdrawing it. The spatula shows small bits of curd.

Coagulation is the starting of transforming liquid milk into the final form of cheese. Fresh cheese is produced from the milk coagulated with staters to form lactic acid. For cured and aged cheese, like cheddar cheese, the addition of a starter is followed by a vegetarian coagulating enzyme (or microbial rennet) to form the curd.

Cutting the curd

This is the process of cutting the firm coagulated curd into cubes of the desired size. It is important to ensure that the curd is ready for cutting. Insert a sanitized glass rod at an angle of 45 degrees and lift it straight. If this makes a clean break in the curd, the curd is ready for cutting. It is important to ensure the cutting is done at the correct time to optimize the yield and quality of cheese. Cutting helps the curd to separate into curd and whey.

Stainless steel curd knives made using stainless steel wires or strips are used for cutting. Two such knives, one vertical and one horizontal are used. Normally, the curd is first cut lengthwise of the vat with the horizontal knife and then length and widthwise of the vat with the vertical knife.

Stirring the curd after cutting

The curd is stirred gently and the speed is gradually increased when the curd cubes get firmed up.

Cooking of cheese curd

Here the curd cubes and whey are heated. The designed temperature and time are followed. The cooking temperature may range from 32⁰ centigrade (90⁰ Fahrenheit) to a maximum of 38⁰ centigrade (100⁰ Fahrenheit); start at 32⁰ C and gradually increase to 38⁰ C. The time and temperature can differ from manufacturer to manufacturer and the type of cheese manufactured. The cooking process makes the curd cubes hard on the outside and soft and watery inside (like case hardening).

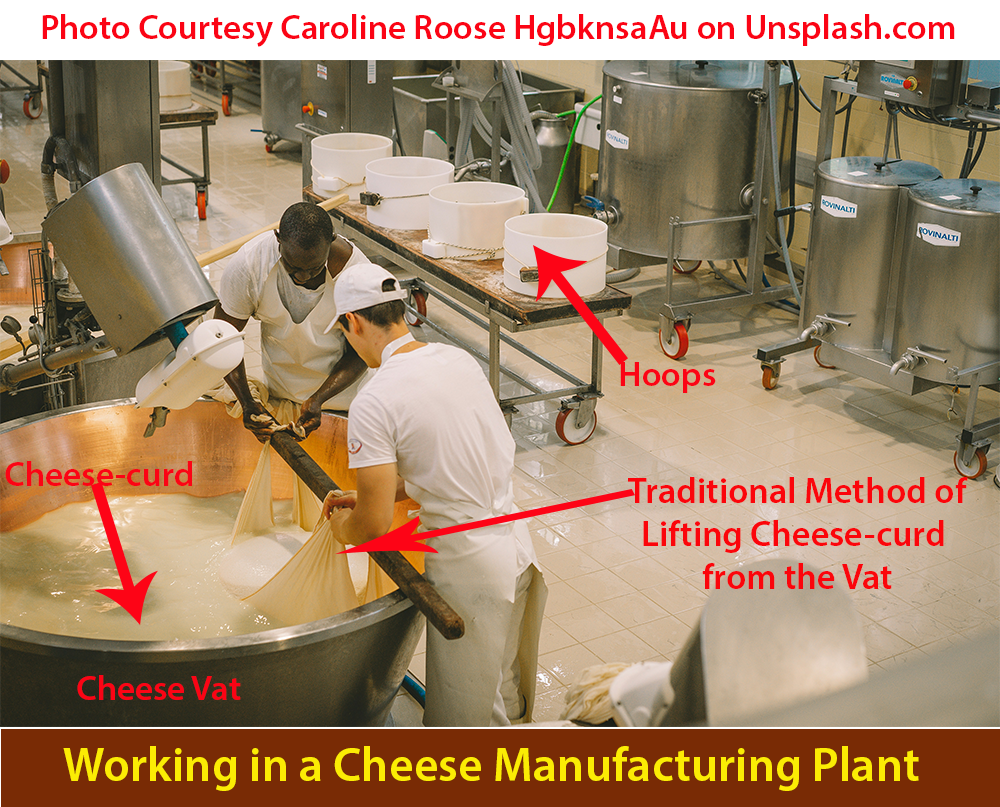

Draining the whey

Here the whey is separated from the curd and drained. At this stage, the curd cubes are reduced to 50% of their size at the cutting stage and they have attained the required consistency, elastic when squeezed. The curd cubes get piled up together. The whey is drained and used for byproducts.

Cheddaring of curd cubes

Cheddaring is a combination of four operations viz. packing, turning, piling, and re-piling. Cheddaring is the process that differentiates ‘Cheddar cheese’ from other cheeses.

Packing

After the whey is drained, the curd cubes are placed in two heaps with the provision of channels for dripping out the whey. This process is called packing and after the whey drips out, the curd cubes are formed into two slabs of curd. These slabs are cut by a cheese knife into the desired size of blocks or strips. The cheese curd can be packed on both sides of the vat and the narrow central space can be used for draining out the whey.

Turning

When the blocks or strips of curd can be handled without breaking, they are turned and rolled bottom-side up in the vat. This process is called turning and is carried out until the curd is ready for milling and salting. The temperature is maintained at around 32⁰ centigrade (90⁰ Fahrenheit).

Piling and re-piling

After the completion of the packing and turning process, the cheese-curd blocks are piled in twos or threes. This is called piling. Then they are re-plied by moving the curd block from top to bottom or vice-versa and this is called re-piling.

The cheddaring process may take two or more hours and it is a critical process for moisture control, and improving the body and texture. The curd blocks become drier, mellow, and silky after cheddaring. There are standard tests to ensure the cheddaring process is completed properly.

Milling

Milling is the mechanical process of cutting the cheddared curd blocks into small pieces (1/2″ to 1″ wide) × (2″ to 3″ long) in a cheese mill. The objective of doing milling is:

- To help further separation and removal of whey.

- To facilitate speedy distribution of salt in the pieces of curd.

- Prepare the pieces of curd for pressing into the final form.

- Milling helps make cheese more uniform in composition.

A power-driven mill is used and when milling is done the pieces of curd fall into the vat itself. The pieces of curd are gently stirred to avoid matting. Milling separates a small amount of whey from the curd. The milled pieces of curd may be rinsed with water to better their physical state for salting and pressing.

Salting

Salting is the process of addition of common salt to the pieces of curd. The amount of salt added should be based on the quantity of curd and the desired results. Neither under-salting nor over-salting of cheese is desirable. The salt in cheese influences its flavor, body, and texture and its keeping quality. Salting should be done at the correct time after doing necessary tests viz. percentage of acidity, pH value, etc.

The objective of salting is:

- It helps further the removal of whey.

- Hardening and shrinking of curd pieces.

- Impeding further formation of lactic acid.

- Generating required quality characteristics in the cheese.

- Flavor

- As a preservative

The quality of salt used is the same as that used for salted butter. The salt may be added directly by sprinkling in 3 equal installments. Some manufacturers may do salting by floating the curd pieces in a brine (concentrated salt water) of appropriate composition. There is no possibility of matting for the salted curd pieces. Some percentage of salt will go along with the whey.

Hooping or molding to shape the cheese

Hoops are rings (wooden, stainless steel, aluminum, or non-metallic) used for pressing out and separating the whey from the curd pieces and the whey is separated using cheesecloth. A mold of a specific shape may be used instead of a hoop. The mold can be circular or rectangular.

It is important to ensure that the curd pieces are ready for hooping viz. salt has fully dissolved, and the curd feels mellow and silky. Hooping should be done at an optimum temperature and many cheese producers do it at 30⁰ centigrade to 32⁰ centigrade. It is important to weigh the curd pieces before filling them into the hoop to ensure a uniform size of cheese.

The arrangement of cheesecloth during hooping is called dressing. Large cheese hoops are lined with cheesecloth before the hoop is filled with curd pieces for pressing. Clothing may not be necessary for small hoops. Cheesecloth helps form a closed outer surface. It is important to line the hoop carefully with cheesecloth to ensure a smooth surface in the finished cheese. The hoops or molds are lined with cloth, filled with curd pieces, and kept ready for pressing.

Pressing

Pressing is the process of forcing the milled and salted curd pieces into the hoops to form cheese blocks of the required shape and size. Pressing can be done on different types of presses viz. screw press, pneumatic press, hydraulic press, etc. The pressure or force applied and its duration should be consistent and as per the designed process.

Pressing may be done in more than one stage like preliminary and final. During pressing, a small amount of whey comes out. The air and whey spaces are closed by the curd pieces during pressing. The complete process of pressing may take more than 10 to 15 hours.

Drying

Drying is done to ensure proper formation of rind or closed outer surface. The steps involved in drying are:

- Careful removal of cheese from the hoop and the removed cheese should be neat, uniform in size, and have a regular shape.

- The cheese is stamped with details viz. date, batch number, type of cheese, name, etc. This is required for identification and record.

- The cheese blocks are kept in the drying room. The drying room is maintained at the proper temperature and relative humidity. It is important to ensure nil mold formation in the drying room.

- The cheese blocks are turned at regular intervals enabling drying of both ends and formation of the desired rind.

Paraffining

Paraffining refers to the process of dipping the cheese for a few seconds in a bath of molten paraffin. Dipping applies a thin layer of paraffin on the surface of the cheese. The edible quality of paraffin is used. Stainless steel tanks are used for preparing the paraffin bath.

The objective of paraffining is:

- To decrease the loss of moisture during curing.

- To control and prevent mold growth.

- Protection of cheese blocks from insects.

Cheese samples are taken for analysis, before paraffining.

The alternative to paraffining is wrapping the cheese blocks with virgin food-grade plastic film. The advantage of plastic wrap is the level of drying the cheese blocks need not be as thorough as required for paraffining.

Curing or ripening or aging

Curing is a process of maturing the cheese by storing it for a prolonged period, 2 to 3 months or more and it is done at low temperature and controlled conditions. Curing profoundly changes the physical, chemical, and bacteriological properties of the cheese and gives a distinctive flavor, body, and texture to the cheese. Curing makes the body of the cheese a little harder and the reason is loss of moisture. The rubbery body of the green cheese turns mellow when ripened. Supervision of the cheese is very important and the place of curing should be kept in good sanitary condition. Curing is also known as the aging of cheese. Curing of cheese enhances its preservation and aroma.

Hard-pressed cheese in its early stages of curing or ripening is called ‘green cheese’ and in this stage, the cheese has yet to develop a distinctive flavor, body, and texture.

Ripening agents in cheese including microorganisms and enzymes have an influence on the rate, extent, and nature of curing or ripening of cheese.

Yield

The yield of cheese depends on the quality of milk, method of cheese manufacturing, manufacturing skills, and curing process. Yield also depends on the composition of milk, mainly its casein and fat content.

The whole process of cheese making described above may take up to 24 hours including pressing (but excluding curing) and the process is labor intensive. To make the process fast and less labor intensive, modern cheese plants adopt continuous cheese-making processes with mechanizing the processes.

You may watch this, this, and this YouTube videos on how cheese is manufactured.

Equipment used in a cheese production plant

The following are the major equipment used in a cheese production plant:

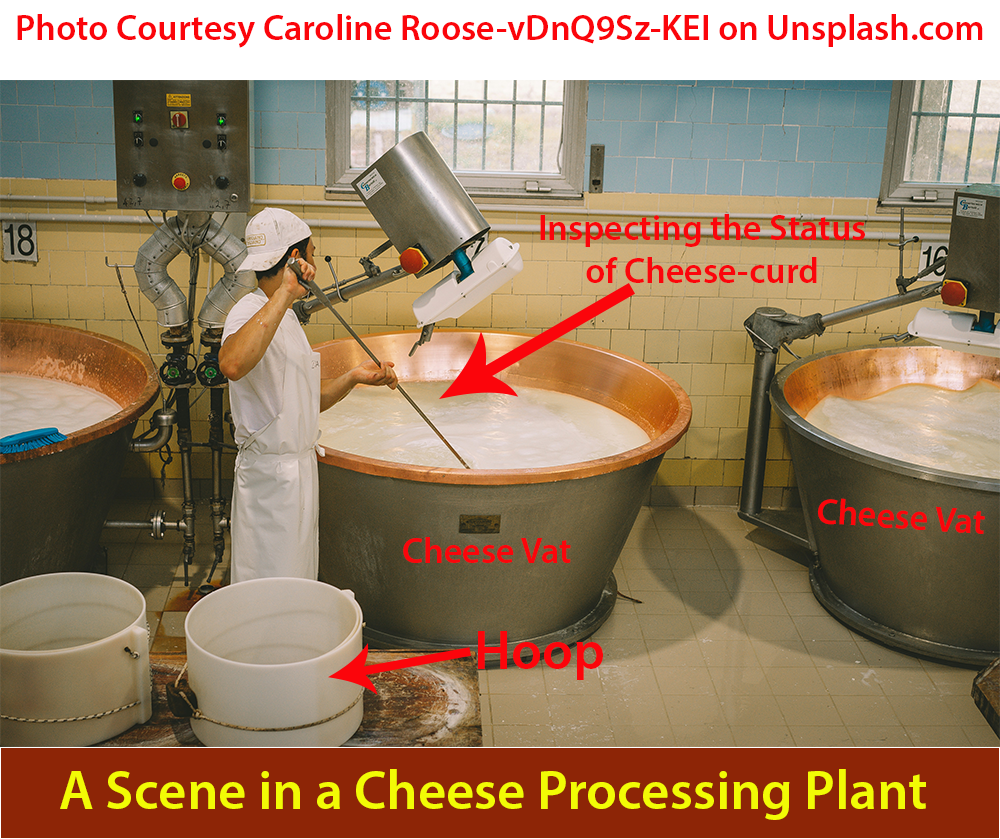

Cheese vat

Rectangular vats with a provision of jacket for uniform distribution of steam and hot water for heating or warming the cheese milk. The vats are fabricated from superior quality austenitic grade stainless steel and good welding practices. The capacity of the cheese vat can be 100 liters to 2000 liters or more. The cheese vat comes with a stainless-steel removable cover and provision for mounting the stirrer.

Stirrer with motor

The stirrer is essential for efficient mixing of starter, additives like color, and rennet, and for uniform heating of milk and curd/whey mixture. The stirrer is driven by a motor and it is possible to vary the stirrer speed. The stirrer is mounted on the vat.

Curd knives

Curd knives are required to cut the cheese-curd into cheese-curd cubes. The knife consists of a stainless-steel frame welded with a series of stainless-steel wires at a definite distance (0.5 to 2.5 centimeters). In the vertical knife, the wires are set vertically and in the horizontal knife, the wires are positioned horizontally. The knives are provided with handles for ease of cutting.

Whey removal

An arrangement is provided for draining out the whey from the cheese vat.

Curd mill

The curd mill is equipped to cut the cheese-curd blocks into small pieces before salting is undertaken. This is a power-driven mechanical cutting process.

Cheese hoops or molds

These are used for molding and pressing pieces of cheese curd into cheese blocks. The material used for making hoops and molds can be stainless steel, wood, or food-grade plastic.

Cheesecloth

Cheesecloth is normally the cotton muslin cloth of the required quality. This is used for lining the hoops and molds to drain the whey during pressing. It also gives the desired surface texture to the cheese blocks.

Cheese press

A cheese press is used for shaping the cheese curd into cheese blocks. The press used can be screw press, pneumatic press, hydraulic press, etc.

Centrifuge

This is used for continuous clarification and standardization of cheese milk.

This is normally a plate type of heat exchanger with multiple sections for pre-heating, heating, cooling, etc. This is used for pre-heating and pasteurization of milk. This can pasteurize the milk continuously. Above are only the major equipment used in a cheese manufacturing plant. There will be many more instruments and accessories that cannot be detailed in this article.

Conclusion

For people who consume cheese regularly, the name cheddar cheese makes them mouthwatering. Now you know how the milk travels from the milk stage to your favorite cheddar cheese, you will appreciate the people who bring this to your dining table.

You may read the following articles

How Mozzarella cheese made in factory

Cheddar Cheese Manufacturing process

Mozzarella Cheese Manufacturing process

What is Vegetarian Cheese made of

References:

Outlines Of DAIRY TECHNOLOGY by Sukumar De, Published by OXFORD University Press, New Delhi.