Introduction

Most of us have heard of diesel generators and have seen them installed in factories, apartment buildings, large temples, malls, cinema theaters, etc. Still, you may be interested in learning what a diesel generator is, the working principle of a diesel generator, the parts of a diesel generator, and the applications of diesel generators. If you are one of those interested persons, please continue reading this article.

A diesel generator has an internal combustion (IC) engine that runs on diesel and this engine is coupled to an alternator or electric generator. The IC engine is the prime mover and it drives the alternator and the alternator produces electric power. You can say a diesel generator converts the mechanical energy of the IC engine to electrical energy.

What is a diesel generator?

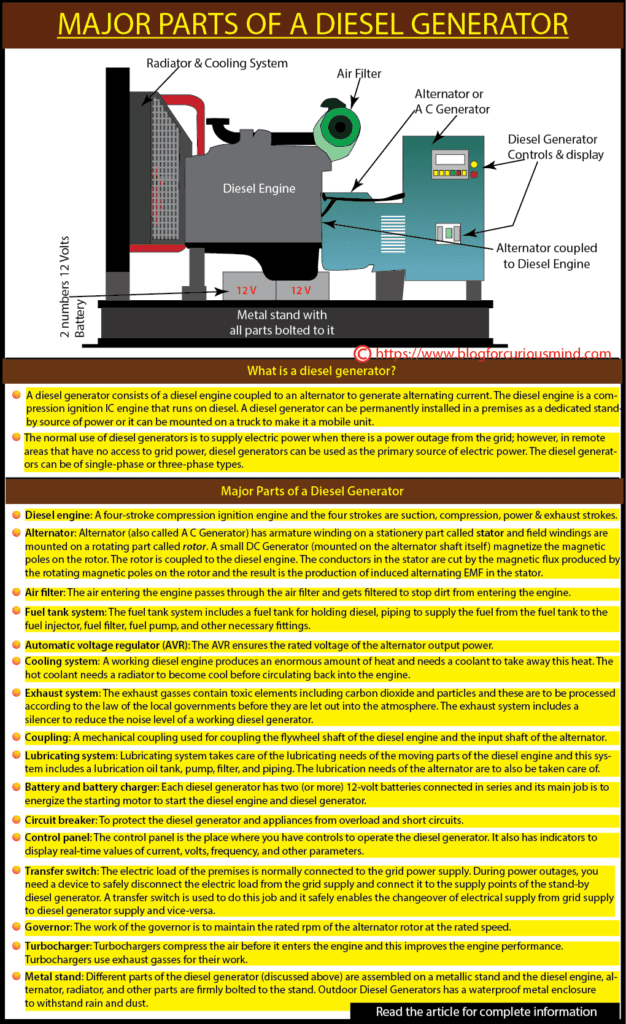

A diesel generator consists of a diesel engine coupled to an alternator (electric generator) and the purpose is to generate alternating current (electrical energy). The diesel engine is a compression ignition IC engine that runs on diesel. Still, it can be designed to run on alternate fuels like CNG (compressed natural gas). A diesel generator is also called a DG or DG set.

A diesel generator can be permanently installed in a premises as a dedicated standby source of power or it can be mounted on a truck to make it a mobile unit.

The normal use of diesel generators is to supply electric power when there is a power outage (no power supply) from the power grid; however, in remote areas with no access to grid power, diesel generators can be used as the primary source of electric power.

There are diesel generators that can output alternating current (AC) or direct current (DC); however, alternating current diesel generators are popular and commonly used. This article discusses alternating-current diesel generators.

The diesel generators can be of single-phase or three-phase types. Single-phase types are used for small shops and residences. Three-phase diesel generators are used in large establishments. The size of the diesel generators can be 7.5 kVA (kilovolt-ampere) to 2000 kVA or more.

The initial cost (capital cost) of installing a diesel generator is appreciably high. Still, it has become necessary in places like hospitals, and industries since the work cannot be stopped when there is a power outage from the grid. The major expense for running a diesel generator is diesel and other costs are the cost of lube oil change, radiator coolant change, and periodic maintenance.

The size of the diesel generator suitable for you should be based on the purpose and end-use. It is normal practice to provide standby power only to meet the emergency needs. In a hospital it is general lighting and services like testing and operating theatres, in a factory it can be critical facilities that cannot be stopped, and in an apartment building, it is the lighting and fans.

The working principle of an alternator in a diesel generator

The alternator of the diesel generator works on the principle of electromagnetic induction. Let us understand ‘what is electromagnetic induction.’

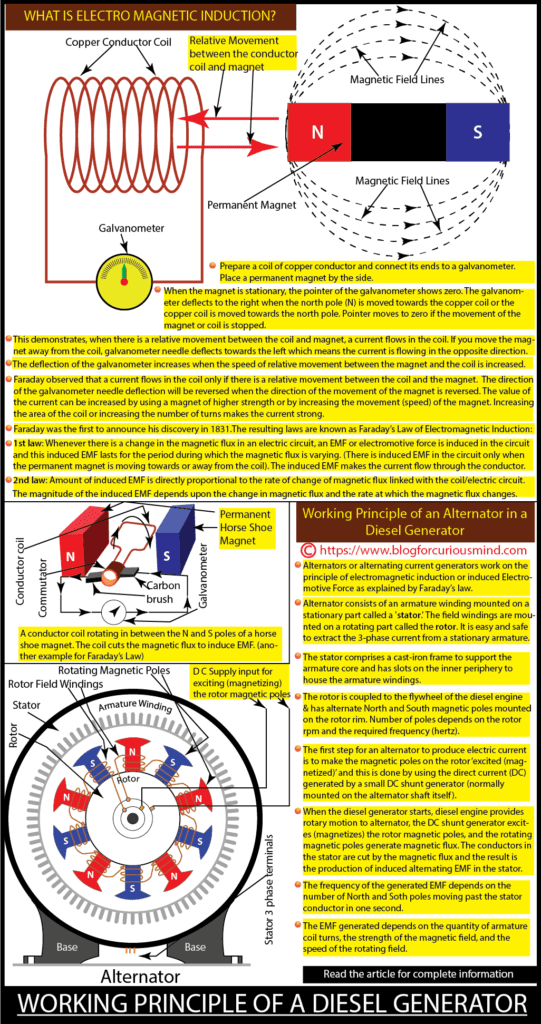

Electromagnetic Induction

Prepare a coil of copper conductor and connect the ends of the coil to a galvanometer. Place a permanent magnet by the side of the coil. When the magnet is stationary, the pointer of the galvanometer shows zero. The needle of the galvanometer deflects to the right when the north pole of the magnet is moved towards the copper coil or the copper coil is moved towards the north pole. The pointer moves to zero if the movement of the magnet or coil is stopped. This demonstrates that if the magnet is moving towards the coil or the coil is moving towards the magnet a current flows in the coil. If you move the magnet away from the coil, the galvanometer needle deflects towards the left which means the current is flowing in the opposite direction.

The deflection of the galvanometer needle increases when the relative movement between the magnet and the coil happens with increased speed. If you reverse the polarity of the magnet (shifting the position of the north and south poles) the deflection of the galvanometer will get reversed.

Michael Faraday observed that a current flows in the coil only if there is a relative movement between the coil and the magnet. The direction of the needle deflection in the galvanometer will be reversed when the direction of the movement of the magnet/coil is reversed. The value of the current in the coil or the deflection of the needle of the galvanometer can be increased by using a magnet of higher strength or by increasing the movement (speed) of the magnet. Increasing the area of the coil or increasing the number of turns makes the current strong.

Electro Magnetic Induction was discovered individually by Michael Faraday in 1831 and Joseph Henry in 1832. Faraday was the first to announce his discovery.

The resulting laws are known as Faraday’s Law of Electromagnetic Induction:

First law

Whenever there is a change in the magnetic flux in an electric circuit/coil, an EMF or electromotive force is induced in the circuit and this induced EMF lasts for the period during which the magnetic flux is varying. (There is induced EMF in the circuit only when the permanent magnet is moving towards or away from the coil). The induced EMF makes the current flow through the conductor.

Second law

The amount of the induced EMF is directly proportional to the rate of change of magnetic flux linked with the coil/electric circuit.

The magnitude of the induced EMF depends upon the change in magnetic flux and the rate at which the magnetic flux changes.

Working principle of alternators

Alternators (also called AC or alternating current generators) work on the principle of electromagnetic induction or induced electromotive force as explained by Faraday’s law.

An alternator consists of an armature winding that is mounted on a stationary part called a ‘stator.’ The field windings are mounted on a rotating part called the rotor. It is easy and safe to extract the three-phase current from a stationary armature.

The stator comprises a cast-iron frame to support the armature core and has slots on the inner periphery to house the armature windings.

The rotor is coupled to the flywheel of the diesel engine (or prime mover). The rotor has alternate North (N) and South (S) magnetic poles mounted on the rotor rim and the number of poles depends on the rotor rpm and the required frequency (hertz).

The first step for an alternator to produce electric current is to make the magnetic poles on the rotor ‘excited (magnetized)’ and this is done by using the direct current (DC) generated by a small DC shunt generator (normally mounted on the alternator shaft itself).

When the diesel generator starts, the diesel engine provides rotary motion to the alternator, the DC shunt generator excites (magnetizes) the rotor magnetic poles, and the rotating magnetic poles generate magnetic flux. The conductors in the stator are cut by the magnetic flux and the result is the production of induced alternating EMF in the stator.

The frequency of the generated EMF depends on the number of North and South poles moving past the stator conductor in one second.

The EMF generated depends on the quantity of armature coil turns, the strength of the magnetic field, and the speed of the rotating field.

View this and this YouTube Video on Faraday’s Law of Electromagnetic Induction.

View this and this (in Hindi) YouTube Video on ‘working of alternators.’

Major Parts of a Diesel Generator

Diesel engine

The diesel engine used in a diesel generator is like what you see on your car or truck; it is a four-stroke compression ignition engine and the four strokes are:

Suction stroke: The inlet valve opens; the piston moves from TDC (top dead center) to BDC (bottom dead center). The suction created in the cylinder allows clean and fresh air to enter the cylinder at atmospheric pressure. At the completion of the suction stroke, the inlet valve is closed.

Compression stroke: Inlet and exhaust valves are closed during compression stroke. The piston moves from BDC to TDC, the air gets compressed and there is an increase in its temperature. At the end of the compression stroke, the fuel injector injects fuel into the cylinder.

Power stroke: The temperature of the compressed air is sufficient to burn the diesel. The power generated by the ignition pushes the piston from TDC to BDC and this power is transmitted to the crankshaft.

Exhaust stroke: Exhaust valve opens and the burnt gasses move out on its own pressure. The piston moves from BDC to TDC pushing the remaining exhaust gasses out. The exhaust valve closes.

Alternator

As explained in the previous section.

Air filter

The air entering the engine passes through the air filter and gets filtered to stop dirt from entering the engine. The air filter removes solid particles including dirt and bacteria.

Fuel tank system

The fuel tank system includes a fuel tank for holding diesel, piping to supply the fuel from the fuel tank to the fuel injector, fuel filter, fuel pump, and other necessary fittings. The capacity of the fuel tank depends on the size of the diesel generator and how many hours it runs in a day or in a week. The capacity of the diesel tank can be 500 liters or even 1000 liters. In some places, there are chances of rainwater entering the diesel tank and, in such places, a fuel water separator may have to be used to separate water from diesel.

Automatic voltage regulator (AVR)

The AVR ensures the rated voltage of the alternator output power.

Cooling system

A working diesel engine produces an enormous amount of heat and needs a coolant to take away this heat. The hot coolant needs a radiator to become cool before circulating back into the engine. The cooling system of a diesel generator consists of a radiator, radiator fan, coolant tank, and connected pipes and fittings.

Higher size diesel generators may have provision to cool the lubricating oil that lubricates the moving parts of the diesel engine.

For more information on radiator, read the article ‘What is a car radiator and how it works.’

Exhaust system

The exhaust gasses generated by the diesel engine are to be safely let into the atmosphere. The exhaust gasses contain toxic elements including carbon dioxide and particles and these are to be processed according to the law of the local governments before they are let out into the atmosphere. The exhaust system includes a silencer to reduce the noise level of a working diesel generator.

Coupling

This is a mechanical coupling used for coupling the flywheel shaft of the diesel engine and the input shaft of the alternator. The coupling ensures the alternator runs along with the diesel engine.

Lubricating system

The lubricating system mainly takes care of the lubricating needs of the moving parts of the diesel engine and this system includes a lubrication oil tank, pump, filter, and piping. Normally, the lubricating system is built into the diesel engine. The lubrication needs of the alternator are to also be taken care of.

Battery and battery charger

Each diesel generator has two 12-volt batteries connected in series and its main job is to energize the starting motor to start the diesel engine and diesel generator. The number of batteries is two or in multiples of two. Once the diesel generator starts working there is an arrangement (like any motor vehicle) to charge the battery.

Circuit breaker

To protect the diesel generator and appliances from overload and short circuits.

Control panel

The control panel is the place where you have controls to operate the diesel generator. It also has indicators to display real-time values of current, volts, frequency, and other parameters.

Transfer switch

Places including industries, hospitals, and apartment buildings use the diesel generator as a stand-by source of supply to be used during power outages from the grid supply. In such situations, the electric load of the premises is normally connected to the grid power supply. During power outages, you need a device to safely disconnect the electric load from the grid supply and connect it to the supply points of the diesel generator. A transfer switch is used to do this job and it safely enables the changeover of electrical supply from grid supply to diesel generator supply and vice-versa.

Governor

The work of the governor is to maintain the rated rpm of the alternator rotor at the rated speed.

Turbocharger

Higher size diesel generators may have a turbocharger. Turbochargers compress the air before it enters the engine and this improves the engine performance. Turbochargers use exhaust gasses for their work.

Metal stand

Different parts of the diesel generator (discussed above) are assembled on a metallic stand and the diesel engine, alternator, radiator, and other parts are firmly bolted to the stand. Outdoor diesel generators have a waterproof metal enclosure to withstand rain and dust.

View this YouTube Video on working of a Diesel generator.

Relation between kilowatts (kW), kilovolt-amperes (kVA), and power factor (PF) of a Diesel Generator.

Kilowatts (kW) is a measure of the actual electric power delivered by the diesel generator and this power is consumed by the equipment and appliances connected to the diesel generator.

Kilovolt-amperes (kVA) is the apparent power of the diesel generator. Kilovolt-amperes include actual power consumed (kW) and reactive power (kVAR) taken by devices including transformers. However, kVAR is not consumed.

The power factor (PF) is the ratio of the actual/real power and apparent power and it ranges from 0 to 1. If an apartment building consumes 900 kW and 1000 kVA, then the power factor is around 0.9.

The nameplate of a diesel generator gives specifications including kW, kVA, power factor, voltage, frequency, and noise level.

How to choose a Diesel Generator for your industry, hospital, or apartment building

The first step in choosing a diesel generator is to make a list of equipment and amenities you want to run using the power supplied by the diesel generator. Mention the purpose of purchasing the diesel generator, to be used as a stand-by source (during outage from power grid) or as a primary power source.

Enter the kilowatt load of each piece of equipment and amenity and total the kilowatt requirement.

Select a reliable brand of diesel generator and discuss your requirements with their engineers. Major brands of diesel generators will have their office or representative near to you.

The actual performance of a diesel generator depends on how the generated power is consumed. Hence, it is wise and crucial to discuss the actual power requirement with the engineers, before finalizing a model.

Applications of a diesel generator

As a standby power source

Short-term power outages from the grid are a common phenomenon in many towns and cities and facilities like hospitals, industry, malls, and apartment buildings have installed diesel generators to serve as a standby power source to run essential equipment during outages.

Portable diesel generator units

These are diesel generators mounted on trucks or trailers and can be easily moved to the place where there is a need for dedicated electrical power. Some of the applications of portable diesel generator units are:

- Power supply for cultural programs or marriage functions held on open premises with temporary structures.

- Construction sites that do not have grid power supply.

- Use by the film and television industry during outdoor shootings.

Diesel-electric Locomotive alternators

Locomotives need electric power to light up the amenities in passenger trains and mechanical/traction power to move the train. The electric power generated by diesel-electric locomotive alternators is used to meet both needs.

Marine diesel generators

Diesel generators are used in ships as a primary source of electric power for lighting, fans, air-conditioning systems, recreation facilities, etc. Some ships may use the power from a diesel generator for propulsion also.

As a dedicated electrical power source

In remote places where grid power is not available like farmland, diesel generators are used to power residential areas, farm appliances, pumps, etc.

Places affected by bad weather

During bad weather conditions like hurricanes and storms, even the best-connected places can suffer power outages for days and weeks. Diesel generators can help such places during rescue operations and meet emergency power requirements of individual residences.

Conclusion

Diesel generators are critical facilities and help us with exigencies. You cannot run a high-tech hospital without a backup power source; just imagine if the doctors were to stop a critical operation because of a power outage! Diesel generators have become an essential facility in hospitals, industries, and residential complexes.

Hope, this article was helpful and could do a little to update your knowledge of diesel generators.

You may read the articles ‘How a submarine sinks and floats on water‘, ‘How a ship floats on water‘, and ‘Parts of a boat and anatomy of a boat‘.

References