Introduction

Even though cheese is one of the oldest foods consumed by humans, cheese was not manufactured on a large scale till the 1850s. During those periods, cheese was made in local form houses using the raw milk obtained from the cows, buffaloes, sheep, and goats raised on the farm. Production of cheese in large batches and the introduction of a dairy or factory system of cheese-making started only between the period 1860 and 1880.

Gradually, improvements in cheese-making productivity were taking place by introducing bigger-sized stainless-steel fabricated units for processing cheese milk into cheese.

In the early 1900s, there were movements like cooperative movement that increased milk production by many folds, and the availability of hygienic tankers for long-distance milk transport resulted in cheese-producing Dairies with excess milk. The demand for processed cheese was on the rise. To utilize the excess available milk and to meet the demand for cheese, cheese makers were badly needed to improve productivity in making cheese.

The traditional cheese-making process has become outdated for many reasons including the following:

- The batch type of cheese production is highly labor intensive.

- The productivity of the batch production method of producing cheese did not meet the market demand.

- The introduction of the cooperative system of milk production, and collection resulted in a huge surplus in milk collection. The surplus milk (after meeting the demand for liquid processed milk) had to be converted into a milk product and cheese is one of the prominent milk products.

The cheese producers were demanding improved, mechanized cheese processing machines with high productivity. They were ready to invest in mechanized and automated cheese-producing lines that could produce cheese continuously.

Read the article ‘How Cheddar Cheese is Made’ to understand the traditional process of making cheddar cheese in detail.

Let us discuss how cheddar cheese is produced on a continuous line of machines.

Mechanization, automation, and continuous production of cheddar cheese

Mechanization and automation of cheddar cheese manufacturing are the basic steps to be realized to achieve the objective of ‘continuous production of cheddar cheese.’

Dairy technologists and engineers started working on the mechanization of cheese production, including cheddar cheese, way back in the late 1960s, 1970s, and 1980s.

What is mechanization of cheese production

The first step of creating a continuous manufacturing line for producing cheese is every cheese-making process should be mechanized and they should be amenable to automation.

Initial processes of cheese production viz. clarification, standardization, and pasteurization of cheese milk were mechanized and automized much before the 1970s. These systems are capable of standardized and pasteurized milk outputs up to 40,000 LPH (Liters Per Hour) or more.

Presently, all the cheese-making processes, including the following are mechanized.

- Ripening of cheese milk

- Coagulation or converting the cheese milk into curd

- Cutting the curd

- Stirring and cooking cheese curd and draining the whey

- Cheddaring of curd cubes

- Milling

- Salting

- Hooping, pressing, and packing the cheese blocks ready for curing/aging

- Converting the aged cheese blocks into small cheese blocks, cheese slices, and cheese spread

What is automation of cheese-making

Mechanizing each of the cheese-making processes is not sufficient to realize the objective of continuous production of cheese. The output from each stage of cheese-making should enter the next stage seamlessly and this chain should not break till the cheese blocks come out duly packed and ready for ripening/aging.

Automation of all individual cheese-making processes and machines helps in achieving the continuous conversion of cheese milk fed at one end of the machine comes out as cheese blocks ready for ripening/aging at the other end.

The mechanization of cheese-making processes has come a long way and along with the technologies of computer engineering, automation, and artificial intelligence available today, dairy technologists and engineers can provide a completely mechanized and automated cheese manufacturing plants to process huge quantity of milk and convert it to varieties of cheese on a continuous process line.

Continuous cheese production

The continuous cheese production plants are completely automized and controlled by computers using artificial intelligence. The human interference will be limited to a few selective jobs like the addition of ripening culture and vegetarian rennet and monitoring the computers to ensure a smooth process.

Continuous cheddar cheese manufacturing

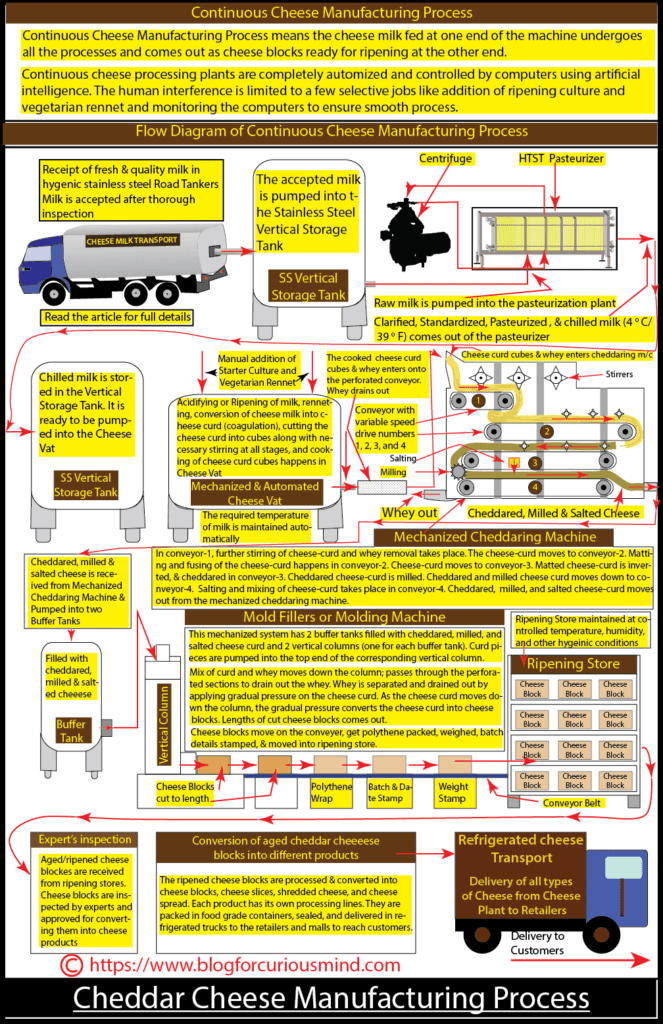

We will briefly discuss a manufacturing line for converting the cheese milk to cheddar cheese on a continuous production line. The cheese milk is fed into the machine at one end, moves through all the processes, and gets converted to cheese blocks ready for ripening at the other end.

Receipt of milk

The fresh milk is received in hygienic stainless-steel temperature-controlled tankers and the milk is tested for quality parameters. The accepted milk is pumped into the large stainless-steel storage tanks.

Filtration, standardization, and pasteurization of milk

The milk in the storage tank is pumped into the continuous pasteurization plant with a centrifuge in the loop and undergoes clarification (filtration), preheating, standardization, pasteurization, and chilling processes. The standardized and pasteurized milk is chilled to less than 4⁰ C (39⁰ F) and stored in an SS vertical storage tank.

The purpose of standardization of cheese milk is to correct the casein/fat ratio to the desired level. Pasteurization is done by the HTST process at 72⁰ C (162⁰ F) for 15 seconds.

Pasteurization plants with throughput of up to 40000 LPH (liters per hour) or more are available.

Read the article ‘What is Pasteurization of Milk? How the Milk is Pasteurized’ to know more.

Cheese vat

The pasteurized milk in the storage tank is pumped into the cheese vat and comes out as cooked cubes of cheese curd. The cheese milk undergoes the following processes in the cheese vat:

- Heating to the required temperatures for ripening, renneting, cooking, etc.

- Add ripening starter (acidifying or ripening of milk)

- Addition of vegetarian rennet

- Coagulation or conversion of liquid cheese milk into semisolid curd

- Cutting the cheese curd into cubes

- Stirring the curd after cutting

- Cooking of cheese-curd

All the above processes are mechanized and happen in an automatic cycle, except for the addition of ripening starter and vegetarian rennet which is done manually. The cheese vat maintains the designed temperature required for each of the above processes.

This kind of cheese vat is suitable for many cheese types including Cheddar, Gouda, Feta, and Mozzarella cheese. These vats may be fabricated with double-circle construction and can be cleaned by a CIP (clean-in-place) system. The heating is accomplished by circulating hot water or steam in the jackets. The cheese vats have automated working with touchscreen controls.

The cooked cheese-curd cubes and whey from the cheese vat move uniformly over a typical drainage mesh conveyor and most of the whey is drained out. The cubes of cheese curd and whey move further on the conveyor and into the mechanized cheddaring machine.

Mechanized Cheddaring machine

The mechanized cheddaring machine has a stainless-steel fabricated frame with four built-in conveyors placed one above the other. The conveyors have a variable-speed drive system. This is a completely enclosed unit engineered to automatically drain the whey, texture, and cheddar the curd, mill the curd, mix dry salt, and smoothen the curd.

The cooked cheese-curd cubes and whey enter the top or first conveyor of the mechanized cheddaring machine.

The first conveyor has stirrers and further stirring of cheese-curd and whey removal takes place. The cheese curd moves down to the second conveyor.

The cheese curd is matted and fused in the second conveyor. The matted and fused cheese curd moves down to the third conveyor.

The matted cheese curd is inverted and cheddared in the third conveyor. At the end of the conveyor, the cheddared cheese-curd is milled. The cheddared and milled cheese curd moves down to the fourth/bottom conveyor.

Salting and mixing of cheese-curd takes place in the fourth conveyor. The cheddared, milled, and salted cheese-curd moves out from the mechanized cheddaring machine.

The drained whey is pumped out and used for byproducts.

The cheddared, milled, and salted mass of cheese curd will still have some whey and it is pumped into the two stainless steel buffer tanks attached to the molding machine or mold fillers.

The alternative design to the mechanized cheddaring machine is known as the Cheddar Master. A Cheddar Master can drain the whey from cheese-curd, cheddaring cheese-curd, salting, stretching, and mellowing of cheese-curd.

Mechanized Cheddaring Machines and Cheddar Masters are available in capacities of up to 9000 kg/hour or more.

Mold fillers or molding machine

Mold filler is a mechanized system with two buffer tanks containing cheddared, milled, and salted cheese curd. There are two vertical columns (one for each of the buffer tanks) to receive the cheddared and salted cheese curd and whey. Salted cheese curd from each buffer tank is pumped into the top end of the corresponding vertical column.

The whey along with the curd settled below it moves down the column, and passes through the perforated sections to drain out the whey. The whey is separated and drained out by applying gradual pressure on the cheese curd. As the cheese curd moves down the column, the increased pressure converts the cheese curd into a continuous block of cheese. The blocks of cheese coming out continuously are cut into fixed lengths and moved on the conveyor belt.

Sealing, labeling, and weighing of cheese blocks

The cheese blocks moving on the conveyor are sealed in virgin polythene, batch details stamped, and weighed as they move on the conveyor. The cheese blocks are packed in cartons, loaded on pallets, and taken into the ripening/aging store.

The ripening store is managed by a computerized system. From the time the cheese blocks arrive in the ripening store till they get ripened and move out of it, all the activities and movements of the cheese blocks are recorded and monitored by the computer system.

View this YouTube video by Amul about their continuous cheese-making dairy units.

Processing of ripened cheddar cheese blocks into different products

The ripened cheese blocks are inspected by experts. The approved cheese blocks are moved from the ripening store into the processing plant to convert them into smaller cheese blocks, cheese slices, shredded cheese, and cheese spread.

Each of these products has their own processing lines. The cheddar cheese products are processed, packed in food-grade containers, sealed, and sent to the product stores maintained at low temperatures. A refrigerated truck transports these products to retailers and malls to reach customers.

You may read the following articles:

How Mozzarella Cheese made in factory

Mozzarella Cheese manufacturing process

Conclusion

The journey of raw milk to cheese blocks, and then from the ripening store to different cheddar cheese products is fantastic, is it not? The milk has to sweat all the way through multiple machines and processes before reaching your dining table as a delicious cheese. Let us appreciate all those dairy technologists, engineers, and cheese makers who invented and created a mechanized and automated line of machines for the continuous manufacturing of cheese and cheese products.

Note: Edits with authentic references are welcome.

References

https://www.journalofdairyscience.org/article/S0022-0302(75)84674-1/pdf#:~:text=Curd%20from%20mechanized%20cheddaring%20equipment,a%20hooping%20station%20(22). (Continuous cheese manufacturing)