Introduction

Yogurt is a popular staple food in many countries, including the West. Internet sources say it originated in Western Asia and the Middle East, and it appears that the word Yogurt is derived from the Turkish word ‘Yoğurmak,’ meaning coagulate, thicken, or curdle.

The history goes like this: Wandering herdsmen used to move with animal skin pouches filled with milk worn on their bodies. The natural enzymes in the pouch curdled the milk, and the body heat of the pouch carrier was sufficient to coagulate the milk into fermented milk or Yogurt. The herdsmen observed that the coagulated milk lasted much longer than milk and tasted good. This is how Yogurt became popular.

Yogurt has different spellings in English, viz. Yogurt, Yoghurt, and Yogourt, but they all mean the same thing.

Organized production of Yogurt on an industrial scale started in 1919 in Barcelona, Spain.

What is Yogurt

Yogurt is a staple food made by bacterial fermentation of milk. The milk used may be derived from cows, buffalo, goats, sheep, yaks, etc. Each milk produces a Yogurt of different varieties. Cow and buffalo milk are normally used for making Yogurt. The bacteria in the culture used for making Yogurt ferment the milk sugar into lactic acid, and lactic acid acts on milk protein to convert milk into Yogurt with a typical tart and sour taste.

You can define Yogurt as a fermented milk product and the fermentation is done with a specific lactic acid bacterial culture viz. Lactobacillus bulgaricus and Streptococcus thermophilus. The SNF (Solids not Fat) content of Yogurt should be 8.25 percent minimum. The Yogurt can be full-fat Yogurt with a minimum of 3.25% milk fat, low-fat Yogurt with 2% or less milk fat, and non-fat Yogurt containing less than 0.5% milk fat. This is as per the U.S. Standard, CFR (Code of Federal Regulations).

Obviously, the major ingredient in Yogurt is milk. The kind of milk used for making Yogurt depends on the type of Yogurt viz. full fat, low fat, or no fat Yogurt. Whole milk is used for full-fat Yogurt, low-fat milk for low-fat Yogurt, and skim milk for no-fat Yogurt. Milk ingredients like cream may be added to adjust the fat content of Yogurt and non-fat milk powder to adjust the SNF content. The CFR specifies a list of allowable dairy ingredients in the Yogurt. Stabilizers are another ingredient the manufacturers may add to Yogurt to enhance the body and texture by improving firmness. Sweeteners, flavors, and fruit preparations are other ingredients allowed in Yogurt.

Yogurt is made from homogenized and pasteurized milk or pasteurized milk. Raw milk should never be used for making Yogurt, since it can cause serious diseases and death. If you have raw milk in your home, you can boil the milk for 6 minutes, cool it to 40 ⁰C (104 ⁰F), and use it for making Yogurt.

Yogurt may be sweetened or added with flavors and fruits to offset or minimize its natural sourness.

Yogurt is said to contain medicinal or healing value and may be one of the reasons of long life of people who consume it.

Contents of Yogurt

Plain Greek Yogurt from whole milk contains

- Water 81 percent

- Protein 9 percent

- Fat 5 percent

- Carbohydrates 4 percent

100 grams of whole milk Greek Yogurt may provide a dietary energy of 97 Kcals. Yogurt has protein, calcium, and other essential Vitamins.

Starter culture for Yogurt

The starter culture used for fermenting milk to Yogurt is Lactobacillus bulgaricus and Streptococcus thermophilus. The purpose of starter culture is to ferment the milk sugar lactose to lactic acid. As the lactic acid increases, there will be a drop in pH value leading to the characteristic formation of soft gel Yogurt. The lactose fermentation produces the typical flavor of Yogurt. Manufacturers may add other bacteria cultures like Lactobacillus acidophilus, and Lactobacillus casei, as probiotic cultures. Probiotic cultures are considered good for human health.

How Yogurt is made

Yogurt is prepared by adding bacteria culture, specifically Lactobacillus bulgaricus and Streptococcus thermophilus to warm milk at around 42 ⁰C (108 ⁰F) and allow it to rest for 6-8 hours at that temperature. Higher temperatures may result in a lumpy texture or separation of whey. Countries may specify that the Yogurt should contain a specified amount of colony-forming units (CFU) of bacteria. The bacteria in the culture transform the milk sugar lactose into lactic acid and thicken the milk with a discrete flavor.

Yogurt production is a simple process. Raw milk is tested for quality, accepted, and clarified to remove dirt. Cream and milk powder are added to maintain the required amount of fat and SNF (solid not fat) percentage. This milk is homogenized, pasteurized, cooled to 42 ⁰C (108 ⁰F), inoculated with Yogurt fermenting culture, and allowed to rest for 6 to 8 hours. The culture ferments the milk into Yogurt.

However, the process after adding culture differs for different types of Yogurts.

To make set Yogurt, the Yogurt is packed in cups immediately after starter inoculation and allowed to set as thick Yogurt.

In the case of stirred Yogurt, the Yogurt is allowed to set completely and then it is added with the required condiments and gently stirred before packing. Depending on the type of Yogurt the added condiments can be fruit, fruit juice, etc.

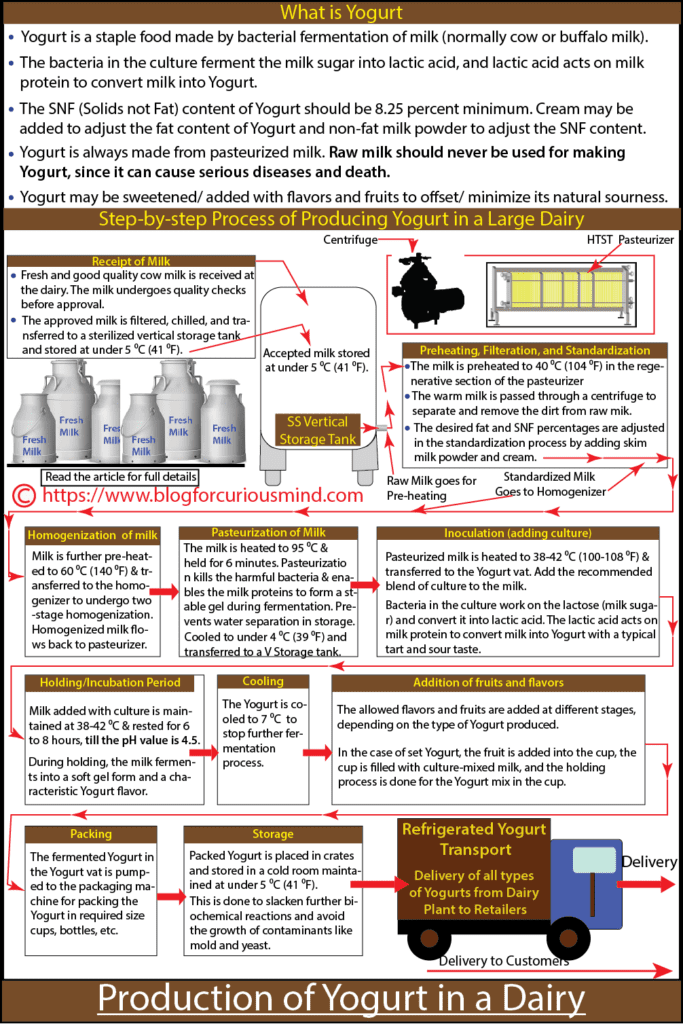

Step-by-step process of producing Yogurt in a large dairy

Receipt of quality milk

Fresh and good quality cow milk is received at the dairy. The milk undergoes quality checks before approval. The approved milk is filtered, chilled, and transferred to a sterilized Stainless steel (SS) vertical storage tank. The milk is stored at under 5 ⁰C (41 ⁰F).

Pre-heating

The milk is preheated to 40 ⁰C (104 ⁰F) in the regenerative section of the pasteurizer (the outgoing hot pasteurized milk transfers its heat to the incoming raw milk).

Filtration or clarification

The warm milk is passed through a centrifuge to separate and remove the dirt from the milk.

Standardization

The SNF (solids not fat) content of the Yogurt should be a minimum of 8.25 percent. The desired fat and SNF percentages are adjusted in the standardization process. This is usually done by adding skim milk powder and cream. This will improve the solid content and texture of Yogurt. A stabilizer may be added.

Homogenization of milk

The milk is further pre-heated to 60 ⁰C (140 ⁰F) in the regenerative section of the pasteurizer and transferred to the homogenizer. The milk undergoes two-stage homogenization at 150/50 bar and the homogenized milk flows back to the pasteurizer.

You may read the article ‘What is Homogenized Milk? How Milk is Homogenized?’ to know more about the homogenization of milk.

Pasteurization

The milk is heated to 95 ⁰C (203 ⁰F) and held for 6 minutes at this temperature. Pasteurization kills the harmful bacteria in the milk. The high pasteurization temperature enables the Yogurt milk proteins to form a stable gel during fermentation and prevents the separation of water while under storage. The pasteurized milk is cooled to under 4 ⁰C (39 ⁰F) and transferred to an SS vertical storage tank.

You may read the article ‘What is Pasteurization of Milk? How the Milk is Pasteurized?’ to know more about the pasteurization of milk.

Inoculation (adding culture)

The pasteurized milk is heated to 38-42 ⁰C (100-108 ⁰F) which is the ideal temperature for fermentation of milk into Yogurt, and transferred to the Yogurt tank or vat. Add the recommended blend of Lactobacillus bulgaricus and Streptococcus thermophilus culture to the milk. The bacteria in the culture work on the lactose (milk sugar) and convert it into lactic acid. The lactic acid acts on milk protein to convert milk into Yogurt with a typical tart and sour taste.

Holding/Incubation period

The milk added with culture is maintained at 38-42 ⁰C (100-108 ⁰F) and allowed to rest at this temperature for 6 to 8 hours, till the pH value reaches 4.5. During holding, the milk ferments into a soft gel form and a characteristic Yogurt flavor.

The incubation period varies depending on the blend of bacteria culture and incubation temperature.

Cooling

The Yogurt is cooled to 7 ⁰C (44 ⁰F) to stop further fermentation process.

Addition of fruits and flavors

The allowed flavors and fruits are added at different stages, depending on the type of Yogurt produced. In the case of set Yogurt, the fruit is added to the cup, the cup is filled with culture-mixed milk, and the holding process is done for the Yogurt mix in the cup.

Packing

The fermented Yogurt in the Yogurt vat is pumped to the packaging machine for packing the Yogurt in required size cups, bottles, etc.

Storage

Packed Yogurt is placed in crates and stored in a cold room maintained at under 5 ⁰C (41 ⁰F). This is done to slacken further biochemical reactions and avoid the growth of contaminants like mold and yeast.

You may watch this and this video on YouTube.

How to make Yogurt at home

Making Yogurt at home is very simple.

What you need

- One liter of homogenized and pasteurized whole milk (non-homogenized and pasteurized milk also will do).

- 0.5 cup of previous day yogurt or recommended quantity of Yogurt culture.

Making process

- Heat the milk in a stainless-steel vessel and slowly bring it to a boil. Turn off the heat.

- Cool the milk to 38-42 ⁰C (100-108 ⁰F). Ensure the temperature with a food-grade digital thermometer. A higher temperature can kill the bacteria in the Yogurt culture and a lower temperature does not allow proper fermentation process.

- Add the previous day’s Yogurt or Yogurt culture and mix well.

- If you have an oven, set the oven to Yogurt, and keep the vessel in the oven for 4 to 5 hours (or as recommended by the oven manufacturer) for incubation. You will know the approximate incubation time after doing Yogurt two or three times.

- Take out the Yogurt from the oven and refrigerate it.

- Note: Do not worry, if you do not have an oven. Wrap the stainless-steel vessel with a woolen cloth and place it in a warm place overnight.

Conclusion

Even though Dahi (curd) is the most preferred fermented milk product for Indians, Yogurt is slowly gaining popularity as a beverage drink, health food, and microbial characteristics. However, its popularity may be limited to the upper middle class and affluence since the cost of Yogurt is appreciably higher than Dahi.

Caution

- This blog article is only for educational purposes and it is not meant to give any personal medical advice. Please seek the advice of your doctor before making Yogurt as part of your diet.

- Yogurt is made from milk. People who are allergic to milk and have issues of lactose intolerance must consult their doctor before adding Yogurt to their diet.

- Consumption of Yogurt made from raw milk can cause serious illness and death. Do not make or consume Yogurt made from raw milk.

References

https://en.wikipedia.org/wiki/Yogurt

https://www.teagasc.ie/rural-economy/rural-development/diversification/production-of-yoghurt

http://www.milkfacts.info/Milk%20Processing/Yogurt%20Production.htm