Introduction

Indian curd, known as Dahi in Hindi, is a popular fermented milk product consumed by most of the Indian population. It is consumed as a part of the daily diet, as a refreshing beverage, or as part of a fast-food snack.

For most Indians, a meal is not complete without Dahi. Popular examples are Dahi chaval (rice) in southern parts of India, Parotta and Dahi in Panjab, Pulao or Biryani with Dahi raita, etc. Lassi is a popular Indian summer beverage made by mixing Dahi and sweetener or salt in a blender (called a mixy in India). Lassi is also made with added flavors and fruits

According to internet sources, Dahi is mentioned in the Rig Veda and ancient Ayurvedic Texts, so you can say Dahi is as old as the Indian Civilization itself.

Dahi is one of the five ingredients used for making Panchamrita, the sacred offering used by Hindus and Jains during pooja. The other 4 ingredients of Panchamrita are cow milk, Ghee, Honey, and sugar.

Conversion of milk into curd is a crucial intermediate stage in the manufacture of butter and ghee, and it is said that around 30% of the milk processed by a milk dairy is converted to curd.

Dahi is said to have medicinal value and may be one of the reasons for the long life of its users.

Dahi can be easily made at home. Packed Dahi/curd is commercially produced and sold by all the milk dairies in India.

This article uses the English word curd and the Hindi word Dahi and both mean the same.

What is Dahi

According to PFA (Prevention of Food Adulteration Act) Rules Dahi is a semi-solid produce made from pasteurized or boiled milk by souring the milk naturally or by a safe lactic acid or bacteria culture. You can define Dahi as a semi-solid fermented product made from pasteurized or boiled milk and the fermentation is achieved using harmless lactic acid or cultures containing bacteria. Dahi must have the same minimum percentage of fat and SNF (solids not fat) as the milk from which it is made, and it may contain added cane sugar.

Dahi (Curd) is produced from homogenized and pasteurized milk or pasteurized milk. Raw milk must not be used for making Dahi, since dangerous bacteria in raw milk can cause severe diseases and death. If you have raw milk with you, boil it for 5 minutes, bring it down to lukewarm heat, and use it for fermenting to Dahi.

Like other fermented milk products, Dahi is considered a probiotic food since it contains beneficial bacteria good for our guts.

The major component in curd is milk. Dahi can be made using cow milk or buffalo milk, whole milk, or standardized milk and the fat and nutrient content of curd differ accordingly. Ingredients of milk viz. cream may be added to adjust the fat content of Dahi and milk powder to adjust the SNF content.

The Indian curd has specific names in each Indian language and some of these names are given below.

- Dahi in Hindi

- Mosaru in Kannada

- Peragu in Telugu

- Thayir in Tamil

- Thayir in Malayalam

- Dahi in Marathi

- Dahi in Gujarathi

- Dahi in Panjabi

- Dohi in Bengali

- Dahi in Odiya

Composition of Dahi

Whole milk Dahi composition

- 85 to 88 percent water

- 5 to 8 percent fat

- 3.2 to 3.4 percent protein

- 4.6 to 5.2 percent Lactose

- 0.70 to 0.75 percent ash

- 0.5 to 1.1 percent Lactic Acid

- The percentage of milk solids concentration can be 5 to 10 percent more in Dahi compared to the milk from which it is made.

Skim milk Dahi composition

- 90 to 91 percent water

- 0.05 to 0.1 percent fat

- 3.3 to 3.5 percent protein

- 4.7 to 5.3 percent Lactose

- 0.70 to 0.75 percent ash

- 0.5 to 1.1 percent Lactic Acid

- The percentage of milk solids concentration can be slightly higher in Dahi compared to the milk from which it is made.

Starter culture for Dahi

A starter culture for Dahi has two functions. The first function is to develop the required quantity of acidity in the milk/curd, and the second function includes the effect of acid formation viz. coagulation, reduction of moisture, formation of texture, and typical flavor production. In addition, starters impart a pleasing acid taste and enhance the shelf life of the fermented product.

Based on the temperature followed the bacteria culture used for fermenting milk into Dahi includes Streptococcus Lactis, Lactococcus Lactis, Streptococcus diacetylactis, Streptococcus Cremoris, Lactobacillus Delbrueckii Subsp. Bulgaricus, and Streptococcus thermophilus. At home, the milk is fermented to curd by adding the previous day’s Dahi as culture. The previous day Dahi will have the necessary bacteria to ferment the milk. Milk can be converted into Dahi by using lemon juice or vinegar, but the Dahi will not have the same taste as that made using the bacteria culture.

How Dahi is made

Dahi is made by injecting bacteria culture into warm milk at around 42 degrees centigrade (108 degrees Fahrenheit) and resting it at that temperature for 4-6 hours or more. Higher temperatures may kill the bacteria and lower temperatures will lead to improper fermentation. The bacteria in the culture convert the lactose into lactic acid and enable curd formation.

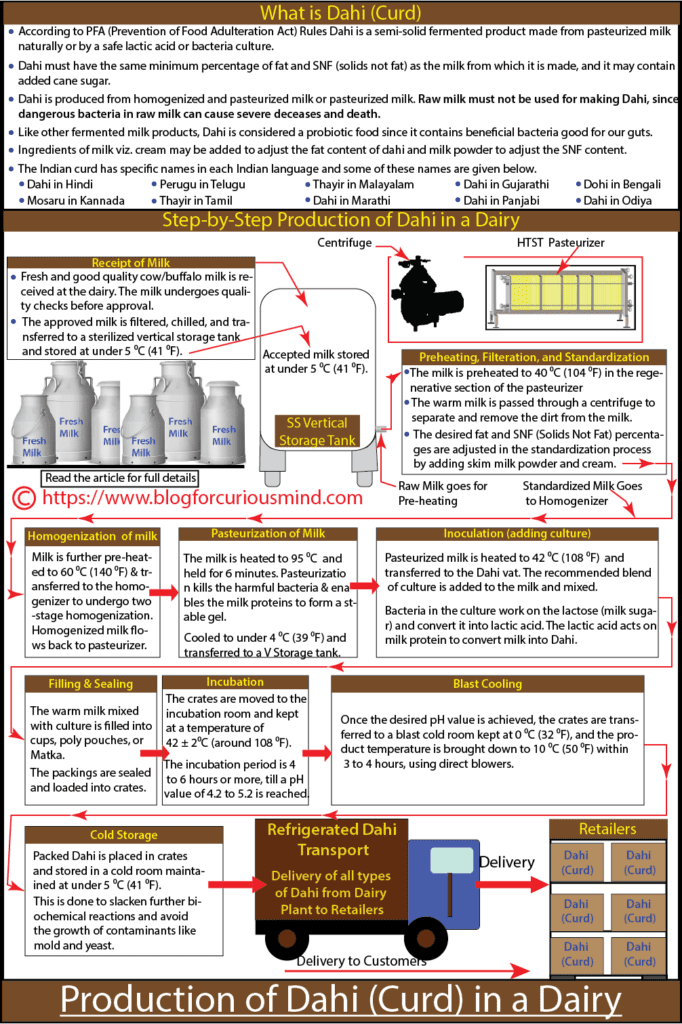

Dahi is made in a simple process. Raw milk is received, tested for quality, and approved. The approved milk is passed through a centrifuge for clarification or to remove dirt; and milk powder & cream are added to keep up the desired amount of SNF (solid not fat) and fat percentage (standardization of milk). The milk is homogenized, pasteurized, cooled to 42 ⁰C (108 ⁰F), and injected with recommended culture. The culture ferments the milk into Dahi in about 4 to 6 hours or more.

Step-by-step process of producing Dahi in a dairy

The following steps are normally followed in a dairy:

Receiving raw milk

Fresh and good quality cow or buffalo milk is received at the dairy in cans or tankers. The milk is inspected for quality and the accepted milk is filtered, chilled, and pumped into the sterilized Stainless steel (SS) vertical storage tanks. The milk is stored at less than 5 ⁰C (41 ⁰F).

Pre-heating

The milk is preheated to 35-40 ⁰C (95-104 ⁰F). This is normally done in the regenerative section of the pasteurization plant and the heat of the outgoing pasteurized milk is used for pre-heating the raw incoming milk.

Filtration or clarification

The pre-heated milk is passed through a centrifuge to filter off dirt from the milk.

Standardization

The pre-heated milk is standardized to the desired milk composition for making curd viz. 2.5 to 3 percent fat and 10 percent SNF (solids-not-fats). Cream and milk powder are added to make up the desired level of fat and SNF. This improves the body of the curd.

Homogenization of milk

The standardized milk is further pre-heated to 60 ⁰C (140 ⁰F) in the regenerative section and sent to the Homogenizer. Homogenization is done at 150/50 bar in a two-stage homogenizer. The homogenized milk is received back into the pasteurization plant.

You may read the article ‘What is Homogenized Milk? How Milk is Homogenized?’ to know more about homogenization of milk.

Pasteurization

The milk is heated to 95 ⁰C (203 ⁰F) and held at that temperature for 6 minutes in an automatic holding tube. The pasteurized milk is cooled to 4 ⁰C (39 ⁰F) and pumped into a storage tank.

You may read the article ‘What is Pasteurization of Milk? How the Milk is Pasteurized?’ to know more about Pasteurization of milk.

Inoculation/adding culture

The pasteurized milk is heated to 42 ⁰C (108 ⁰F) and transferred to the culture inoculation tank or vat. The prescribed amount of recommended starter bacteria culture is added and stirred. The starter bacteria culture can be a combination of one or more bacteria cultures discussed in the preceding paragraphs.

Filling and sealing

The warm milk mixed with culture is filled into cups, poly pouches, or Matka. The packings are sealed and loaded into crates.

Incubation

The crates are moved to the incubation room and kept at a temperature of 42 ± 2⁰C (around 108 ⁰F). The incubation period is 4 to 6 hours or more, till a pH value of 4.2 to 5.2 is reached.

Blast cooling

Once the desired pH value is achieved, the crates are transferred to a blast cold room kept at 0 ⁰C (32 ⁰F), and the product temperature is brought down to 10 ⁰C (50 ⁰F) within 3 to 4 hours, using direct blowers.

Cold storage

The crates are transferred to cold storage and kept at under 5 ⁰C (41 ⁰F) till the time of dispatch.

Despatch

The curd is despatched in refrigerated trucks maintained under 5 ⁰C (41 ⁰F).

Types of Dahi

Dahi can be broadly classified into the following types/categories:

- Dahi for direct consumption

- Dahi to produce white butter (desi butter)

- Dahi for making Chakka, Shrikhand, and Lassi

- Dahi made from whole milk, skim milk, and standardized milk

- Dahi with added sugar and fruits

Dahi for direct consumption is sweet or mildly sour with a pleasing flavor.

Making Dahi at home

It is simple to make Dahi at home. Boil the milk for 5 minutes and cool down to lukewarm (hand-hot). Add 2 to 3 teaspoons of the previous day’s Dahi, mix well, and allow it to sit undisturbed overnight. If the weather is cold, wrap the vessel used for curd setting with woolen cloth to keep it warm. If you have an electric cooker, you can use it for setting curd. Follow the instructions of the cooker manufacturer.

Conclusion

Dahi is a major staple food in India and for many Indians, the meal is incomplete without Dahi. The curd is so tasty that even people who are averse to consuming milk are happy to consume Dahi. Hope this article was helpful to you.

Caution

- Dahi is made from milk. If you have issues of milk allergy and/or lactose intolerance, please discuss them with your doctor before making Dahi as part of your diet.

- Never consume Dahi made from raw milk, Dahi made from raw milk can cause serious diseases and death.

References

https://niftem.ac.in/newsite/pmfme/wp-content/uploads/2022/08/PPT_dahi-processing.pdf PDF can be downloaded

https://en.wikipedia.org/wiki/Dahi_(curd)