Introduction

We all know flattened rice or poha and tasted many dishes made using it as a major ingredient, including kanda batata poha and chiwda. Flattened rice is popularly known as poha, as it is known in Hindi. Though there is a name in every Indian language for flattened rice, we will use the name ‘poha’ in this article since it is generally understood by many people.

Even though poha has been made and consumed in Indian homes for hundreds of years, it is unclear who invented it. But it was mentioned in Mahabharata, where Lord Krishna’s gurukul friend Sudhama offers raw poha to him and Lord Krishna relishes it. Even today, raw poha is one of the major offerings to Lord Krishna by his devotees at many temples.

Do you know how poha is made in India? Yes, you are right; poha is made from paddy (rice). This article explains the step-by-step process of making poha from paddy in a poha-making factory.

Poha is traditionally made in paddy (rice) cultivating regions viz. Southeast Asia and South Asia. Apart from India, poha is popular in Bangladesh and Nepal. Flattened rice is made from a variety of raw harvested paddy (rice) and it is consumed in other Asian countries also viz. Cambodia, Myanmar, Philippines, Thailand, and Vietnam.

How poha is made from rice/ paddy?

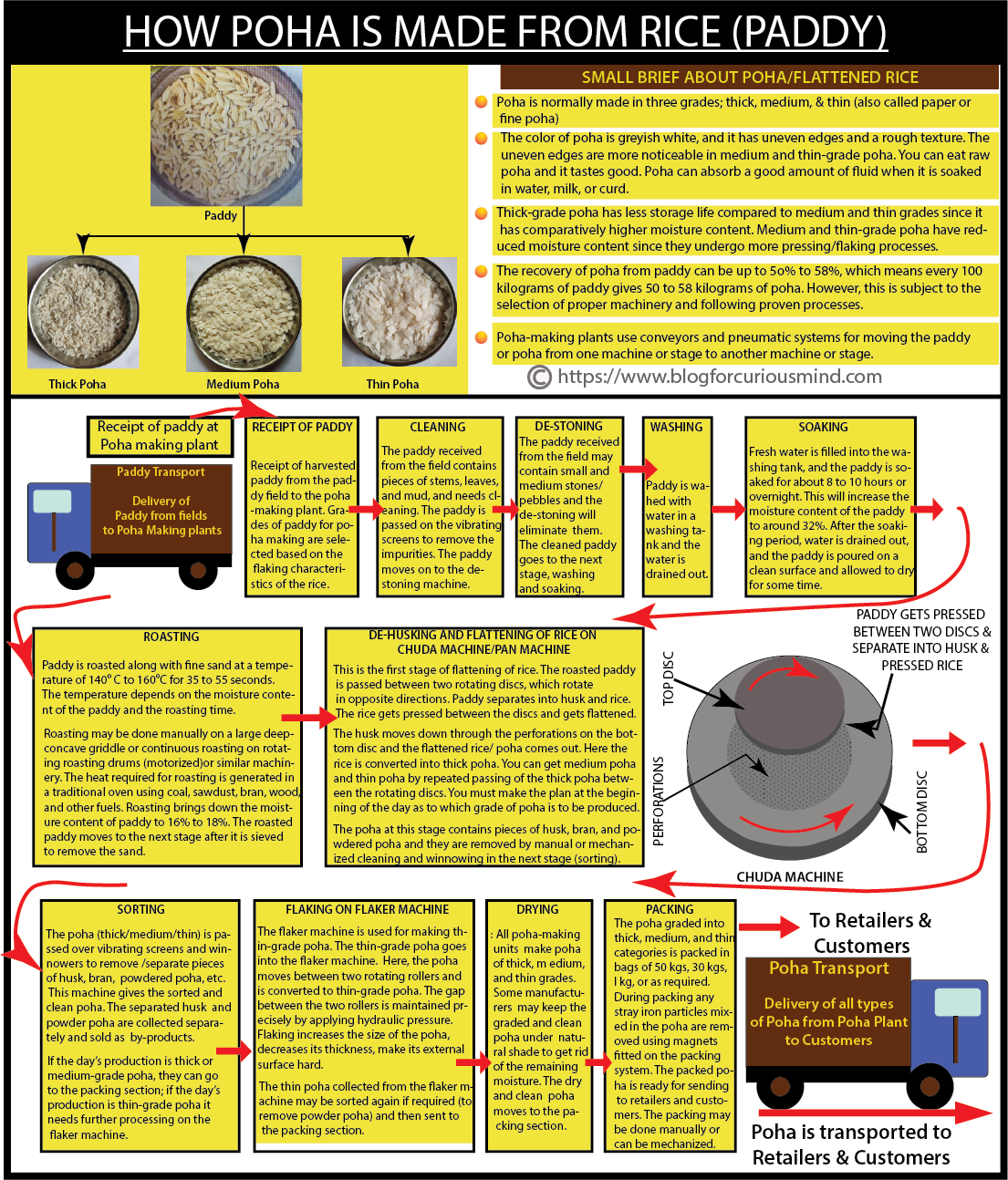

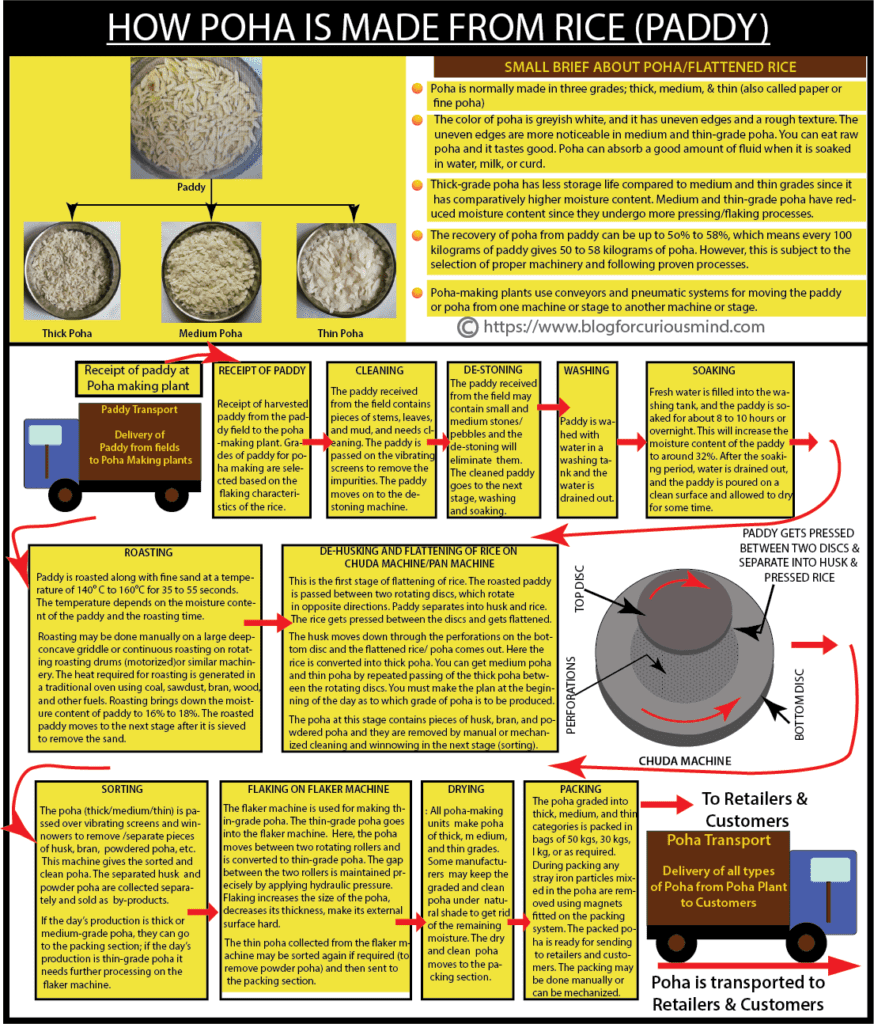

Poha is made from soaked and roasted paddy (rice) and is normally made in three grades viz. thick, medium, and thin. The thickness of the ‘thick poha’ can be around 1 millimeter, ‘medium poha’ around 0.6 millimeters, and ‘thin poha’ 0.5 to 0.3 millimeters. Thin poha is also called paper poha or fine poha. The step-by-step process followed in a poha-making factory is explained below:

Step 1: Receipt of harvested paddy from the paddy field to the poha-making plant. Grades of paddy suitable for poha making are selected and transported to the poha plant. There are specific grades of paddy suitable for making poha and the selection is based on the flaking characteristics of the rice.

Step 2, cleaning: The paddy received from the harvesting field contains pieces of stems, leaves, and mud, and needs cleaning. The paddy is passed on the vibrating screens to remove the pieces of stems, leaves, and dirt/mud. The paddy moves on to the de-stoning machine.

Step 3, De-stoning: The paddy received from the field may contain small and medium stones/pebbles and the de-stoning will help eliminate them. The cleaned paddy goes to the next stage, washing and soaking.

Step 4, washing: Paddy is washed with water in a washing tank and the water is drained out.

Step 5, soaking: Fresh water is filled into the washing tank, and the paddy is soaked at room temperature for about 8 to 10 hours or overnight. This will increase the moisture content of the paddy to around 32%. After the soaking period, water is drained out, and the paddy is poured on a clean surface and allowed to dry for some time.

Step 6, roasting: Paddy is roasted along with fine sand at a temperature of 140⁰ C to 160⁰C for 35 to 55 seconds. The temperature depends on the moisture content of the paddy and the roasting time; a higher roasting time may be needed when the temperature is at the lower end of the range.

Roasting may be done manually on a large deep-concave griddle or continuous roasting on rotating roasting drums (motorized)or similar machinery. The heat required for roasting is generated in a traditional oven by coal, sawdust, bran, wood, and other fuels.

Roasting brings down the moisture content of paddy to 16% to 18%. The roasted paddy moves to the next stage after it is sieved to remove the sand. The roasting temperature and roasting duration should be kept moderate to avoid popping.

The roasted paddy goes to the chuda machine for de-husking and flattening (some call this a pan machine).

Step 7 De-husking and flattening of rice on chuda machine/pan machine: This is the first stage of flattening of rice. The roasted paddy is passed between two rotating discs, which rotate in opposite directions around their vertical axis. The roasted paddy is separated into husk and rice. The rice gets pressed between the discs and gets flattened.

The husk moves down through the perforations on the bottom disc and the flattened rice/ poha comes out from the chuda machine. This is the first stage of flattening the rice and here the rice is converted into thick poha. You can get medium poha and thin poha by repeated passing of the thick poha between the rotating discs. You must make the plan at the beginning of the day as to which grade of poha is to be produced.

The poha at this stage contains pieces of husk, bran, and powdered poha and they are removed by manual or mechanized cleaning and winnowing in the next stage (sorting).

Step 8, sorting: The poha (thick/medium/thin) is passed over vibrating screens and winnowers to remove /separate pieces of husk, bran, powdered poha, etc. This machine gives the sorted and clean poha. The separated husk and powder poha are collected separately and sold as by-products.

If the day’s production is thick or medium-grade poha, they can go to the packing section; if the day’s production is thin-grade poha it needs further processing on the flaker machine.

Step 9- flaking, on the flaker machine: The flaker machine is used for making thin-grade poha. The thin-grade poha goes into the flaker machine. Here, the poha moves between two rotating rollers and is converted to thin-grade poha. The gap between the two rollers is maintained precisely by applying hydraulic pressure. Flaking increases the size of the poha, decreases its thickness, makes its external surface hard and it does not break even after it reaches the customer.

The thin poha collected from the flaker machine may be sorted again if required (to remove powder poha) and then sent to the packing section.

Step 10-drying: All poha-making units make poha of thick, medium, and thin grades. Some manufacturers may keep the graded and clean poha under natural shade to get rid of the remaining moisture. The dry and clean poha moves to the packing section.

Step 11-packing: The poha graded into thick, medium, and thin categories is packed in bags of 50 kgs, 30 kgs, I kg, or as required. During packing any stray iron particles mixed in the poha are removed using magnets fitted on the packing system. The packed poha is ready for sending to retailers and customers. The packing may be done manually or can be mechanized.

View this YouTube Video and this YouTube Video (Hindi) to understand the poha making process.

Small brief about poha/flattened rice

- The color of poha is greyish white, and it has uneven edges and a rough texture. The uneven edges are more noticeable in medium and thin-grade poha. You can eat raw poha and it tastes good. Poha can absorb a good amount of fluid when it is soaked in water, milk, or curd.

- Thick-grade poha has less storage life compared to medium and thin grades since it has comparatively higher moisture content. Medium and thin-grade poha have reduced moisture content since they undergo more pressing/flaking processes.

- Select a quality brand poha and ensure the poha in the packet looks good. Store poha in an air tight bottle and consume it within 3 months.

- The recovery of poha from paddy can be up to 5o% to 58%, which means every 100 kilograms of paddy gives 50 to 58 kilograms of poha. However, this is subject to the selection of proper machinery and following proven processes.

- Poha-making plants use conveyors and pneumatic systems for moving the paddy or poha from one machine or stage to another machine or stage.

Major machinery and equipment required in a poha making plant

Machinery

- Paddy cleaner

- De-stoner

- Roasting machine

- Flattening machine (chuda machine)

- Flaking machine

Equipment

- Elevators to move/lift the paddy

- Soaking tanks

- Vibrating screens(sieve) and winnower

- Conveyors for moving the paddy/poha from one machine to another machine

- Weighing scale

- Packing machine

- Bag sealing/sewing machine

- Transport vehicles

View this YouTube Video (Hindi) to understand the machinery used in poha-making

Different names of flattened rice in Indian languages

Rice flakes, flattened rice, pressed rice, and pounded rice, are the different English names for our own popular breakfast staple food poha. Some of the names for poha in Indian languages are:

- Avalakki in kannada

- Atukulu in Telugu

- Aval in Tamil and Malayalam

- Pohe in Marathi

- Povu in Konkani

- Pauwa in Gujarati

- Chuda in Odia

Dishes made from poha

- Poha is tasty to eat, easy to digest, easy and fast to cook, and can even be eaten raw. The dishes made from poha can be soft, crisp, crunchy, or chewy.

- Poha is a versatile food, it can be made into a yummy breakfast like the famous kanda batata poha, a crunchy evening snack like chivda, or when you are in a hurry just rinse poha in water and eat it with jaggery.

- Poha is one of the major food items used for making yummy breakfasts in Maharashtra, Gujarat, Karnataka, Madhya Pradesh, Rajasthan, and other states.

- In Karnataka and some other southern parts of India, poha is added as an ingredient while preparing dosa batter and it makes dosas light and delicious.

- Poha made from red rice is available for health-conscious people. Compared to normal poha, poha made from red rice has more dietary fiber and antioxidants.

- Poha is not known to have any side effects. However, too much of any food is not good for the human body, so moderate quantities as recommended by your doctor are preferred.

- If you are undergoing any medical treatment, take the advice of your doctor before adding poha to your diet.

- If you are in a hurry, and needs immediate snack, poha comes to your rescue. The image below shows few recipes using poha.

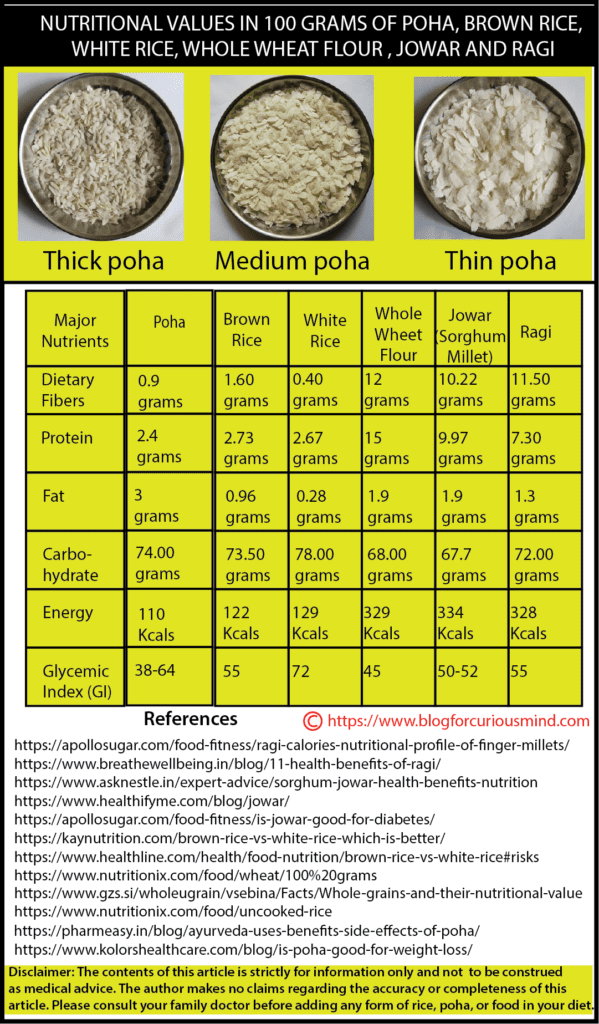

Nutritional value of poha

- Poha contains approximately 1 mg of iron in every 100 grams of poha. The reason for the increased iron content may be the processing equipment used for making poha from rice is mainly made from iron.

- Like rice, poha is gluten-free and can be considered by people who are allergic to gluten.

- Poha retains more dietary fibers compared to white rice due to minimal processing in case of poha

- Poha contain vitamins B1, B3, and B6.

- Poha contains approximately 0.9 grams of dietary fiber per 100 grams of poha.

- Poha with its high carbohydrate content is a good source of energy especially in a dish that contains ingredients like ground nuts, grated coconut, green peas, potato, onion, etc. (like kande batata poha).

- Poha may have antioxidant properties

- Poha is easy to digest

Conclusion

Poha is a major ingredient for breakfast and snacks in many parts of our country including major consumers of poha viz. Maharashtra, Karnataka, Gujarat, Madhya Pradesh, and Rajasthan. And it is interesting to know how poha is made from paddy (rice). Hope this article was useful to you.

You may read the following articles

What is Sabudana and how it is made in India

Caution

The contents of this article are strictly for information only and are not to be construed as medical or dietary advice. Please consult your family doctor before adding any form of flattened rice or poha or any food to your diet.

References